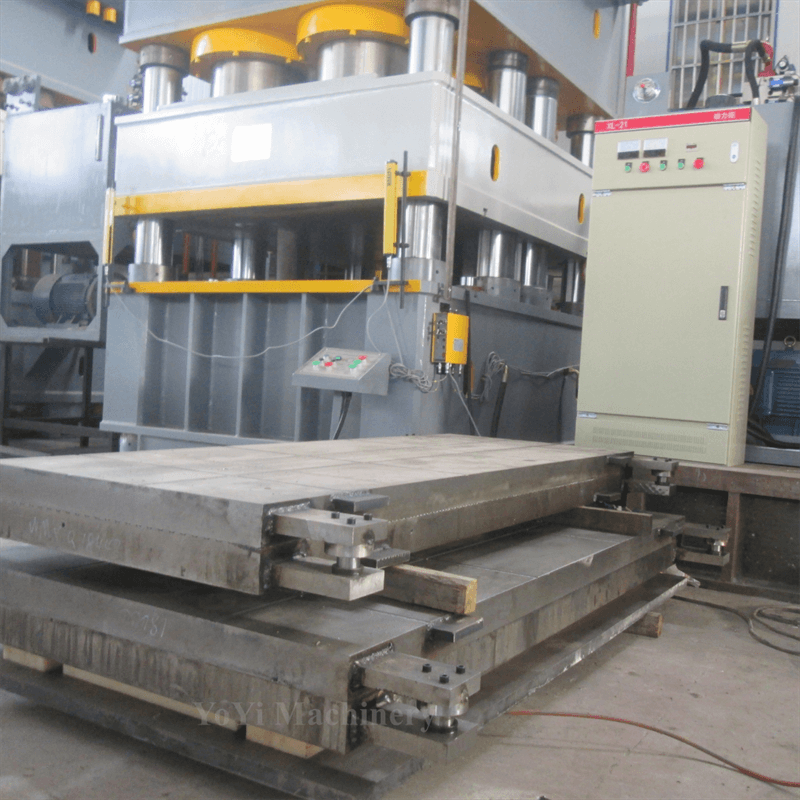

Steel Door Press Machine, Door Mold Design

A steel door press machine is an industrial machine used to manufacture steel doors by shaping and forming metal sheets into the desired door design. This door panel hydraulic press applies high pressure to the metal sheets, pressing it into molds or dies to create the final product.

Key Components:

- Frame: The frame of the steel door press machine provides the structural support and rigidity needed to withstand the high pressure applied during the door forming process.

- Hydraulic press system: The press system is responsible for generating the force required to shape the steel sheets into the desired door design.

- Door mold: The door mold is a critical component of the steel door press machine. It consists of two parts – the cavity and the core – which are designed to create the desired door shape and pattern when pressed together.

- Pressing table: The pressing table is the surface on which the steel sheets are placed and aligned before the pressing process begins.

- Control system: The control system manages the operation of the steel door press machine, including the force applied during the pressing process, the speed of the press, and the duration of the press cycle.

- Safety features: Steel door press machines are equipped with safety features, such as emergency stop buttons, guards, and interlocks, to protect operators from potential hazards during the door manufacturing process.

How Does a Steel Door Press Machine Work?

Steel door press machines operate by applying controlled pressure to a metal sheet to mold it into the shape of a door. Typically, the process begins with a steel sheet that is placed in the machine. The machine then applies significant force, pressing the steel into a door mold or die. The pressure used is carefully calibrated to ensure that the steel does not get damaged while still forming a strong, durable door.

The press machine can also be equipped with additional features such as punching, trimming, and embossing capabilities to add functionality and design to the door. Once the steel has been pressed into the desired shape, it may undergo further treatments, such as coating or painting, to enhance its appearance and corrosion resistance.

Operation of a steel door press machine:

- Prepare the steel sheets: The steel sheets are cut to the required size and thickness according to the door design specifications.

- Place the steel sheet on the pressing table: The steel sheet is positioned and aligned on the pressing table, ensuring that it is properly placed in the mold cavity.

- Pressing process: The hydraulic press system applies high pressure to the steel sheet, forcing it into the door mold cavity. The steel sheet conforms to the shape of the mold, creating the desired door design.

By following this process, a steel door press machine can efficiently produce high-quality steel doors that meet the desired specifications and aesthetic requirements.

Main Technical Parameters:

1) Nominal force: 30000 Kn

2) Return force: 425 Kn

3) Slide Stroke: 500 mm

4) Max. working pressure of hydraulic system: 25 Mpa

5) Max. Opening Height: 600 mm

6) Slider Speed

a. Descending: 100-120 mm/s

b. Working: 4-8 mm/s

c. Returning: 100-120 mm/s

7) Effective working table size: 1500 mm × 2500 mm

8) Motor Power: 60KW

9) Structure: three-beam, eight-column, single action

casssia@yoyimachinery.com

casssia@yoyimachinery.com