Introduction

In today’s rapidly evolving construction industry, the demand for sturdy and durable door frames is ever-present. Steel door frames offer unparalleled strength and longevity, making them a popular choice among builders and homeowners alike. However, crafting these frames requires precision machinery and expertise. In this article, we’ll explore the intricate process of steel door frame making machines, covering everything from their components to their operation and maintenance.

Understanding Steel Door Frame Making Machines

What are Steel Door Frame Making Machines?

Steel door frame making machines are specialized equipment designed to fabricate steel door frames with utmost accuracy and efficiency. These machines encompass a range of processes, including cutting, bending, welding, and assembly, to produce high-quality door frames suitable for various applications.

Components of Steel Door Frame Making Machines

To grasp the functionality of steel door frame making machines, it’s essential to familiarize oneself with their key components:

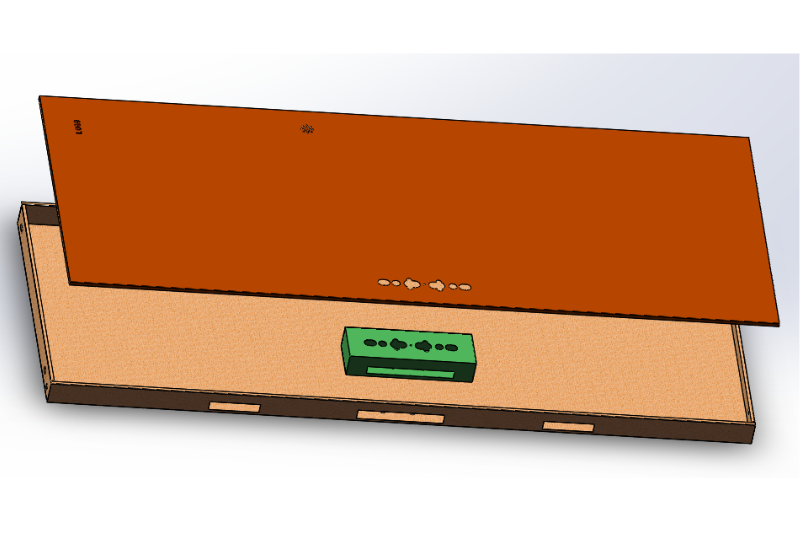

Steel Door Frame Roll Forming Machine

The steel door frame roll forming machine is the heart of the operation, responsible for shaping the steel sheets into precise profiles that form the basis of the door frames.

Saw Cutting Machine

This component is utilized for cutting the steel door frame into 45 degree.

Hydraulic Press Brake/ Steel Door Frame Bending Machine

The hydraulic press brake is also called steel door frame bending machine for bending the steel door frame profiles to achieve the desired angles and shapes, crucial for creating robust door frame structures.

Welding Station

At the welding station, individual components are fused together using advanced welding techniques, guaranteeing seamless joints and structural integrity.

Assembly Line

In the final stage, the assembled components undergo rigorous quality checks before being packaged and dispatched for installation.

Operational Insights and Best Practices

Operating a Steel Door Frame Making Machine

Operating a steel door frame making machine demands a combination of technical expertise and adherence to safety protocols. Here’s a step-by-step overview of the process:

Step 1: Material Preparation

Begin by loading the raw steel sheets onto the roll forming machine, ensuring they are properly aligned and secured for processing.

Step 2: Profile Formation

Activate the roll forming machine to shape the steel sheets into the desired profiles, adjusting the settings as per the specifications of the door frames.

Step 3: Cutting and Bending

Once the profiles are formed, utilize the saw cutting machine and press brake to cut and bend the components with precision, following the designated measurements.

Step 4: Welding and Assembly

At the welding station, employ skilled welders to join the components together seamlessly, maintaining structural integrity and aesthetic appeal.

Advancements in Steel Door Frame Making Technology

Innovations in Roll Forming Techniques

Recent advancements in roll forming technology have revolutionized the steel door frame manufacturing process, enabling faster production speeds, higher precision, and greater customization options.

Integration of Automation

The integration of automation systems, such as robotic welding and CNC control, has streamlined production workflows and minimized manual intervention, leading to increased productivity and cost-efficiency.

Enhanced Quality Control Measures

With the implementation of advanced inspection systems and quality control measures, manufacturers can now ensure consistency and compliance with industry standards, thereby enhancing product reliability and customer satisfaction.

FAQs (Frequently Asked Questions)

1. How durable are steel door frames compared to other materials? Steel door frames are renowned for their exceptional durability, outlasting traditional materials such as wood or aluminum in terms of longevity and resistance to wear and tear.

2. Can steel door frames be customized to fit non-standard openings? Yes, modern steel door frame making machines offer extensive customization options, allowing manufacturers to tailor the dimensions and configurations of door frames to suit specific project requirements.

3. Are steel door frames susceptible to corrosion? While steel is inherently prone to corrosion, proper surface treatment and coating techniques can significantly mitigate the risk, ensuring long-term durability and performance.

4. Can steel door frame making machines produce frames of different sizes? Yes, most machines are adjustable to accommodate various frame dimensions.

5. Are steel door frame making machines suitable for small-scale production? Yes, there are machines available that cater to the needs of small-scale manufacturers.

6. Can steel door frame making machines work with different types of steel? Yes, these machines can process various grades and thicknesses of steel.

Conclusion

In conclusion, steel door frame making machines play a pivotal role in the door industry, facilitating the efficient production of robust and reliable door frames. By leveraging advanced technologies and best practices, manufacturers can meet the growing demand for high-quality steel door frames while ensuring optimal performance and customer satisfaction.