Laser cut metal screens have become a dominant feature in modern architecture and design, offering a perfect blend of visual elegance, durability, and functional versatility. Whether you’re designing a luxurious residence, a commercial facade, or a tranquil garden retreat, these custom metal panels are the ideal solution for privacy, shading, ventilation, and artistic expression.

Engineered with precision and crafted from high-quality metals, laser cut metal screens bring your architectural vision to life while ensuring long-term structural integrity and minimal maintenance.

What Are Laser Cut Metal Screens?

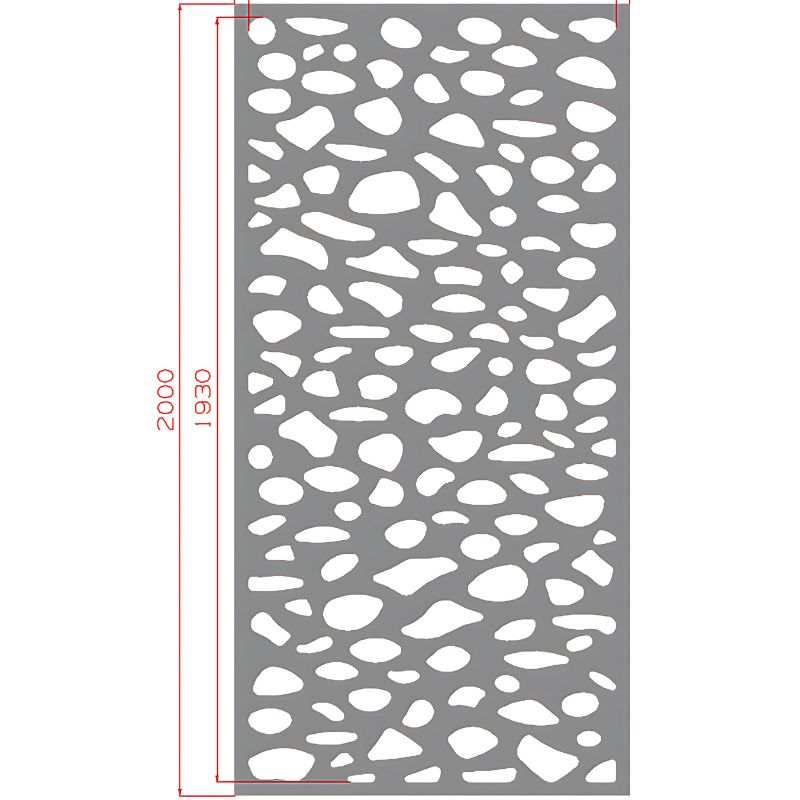

Laser cut metal screens are decorative or functional panels made by cutting detailed patterns into metal sheets using advanced laser cutting technology. These screens can be fabricated from a wide range of metals including aluminum, stainless steel, corten steel, and mild steel, and are often used for both interior and exterior applications.

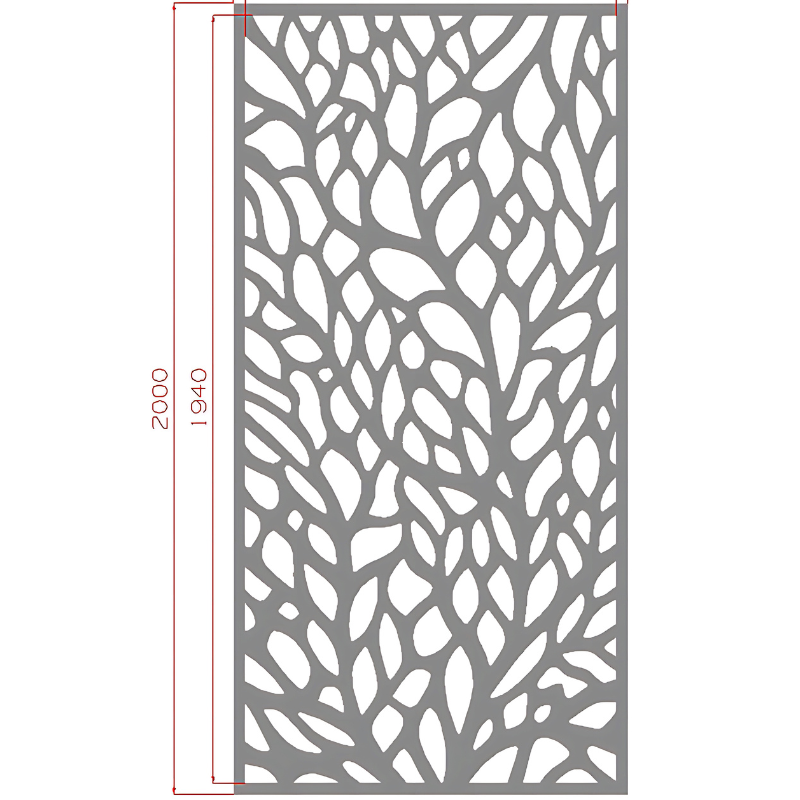

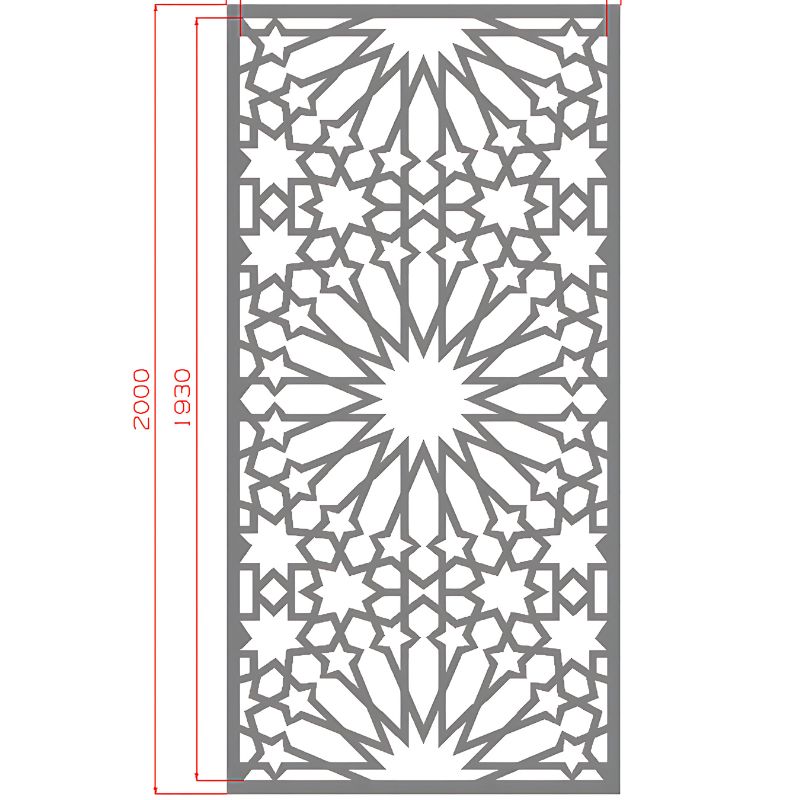

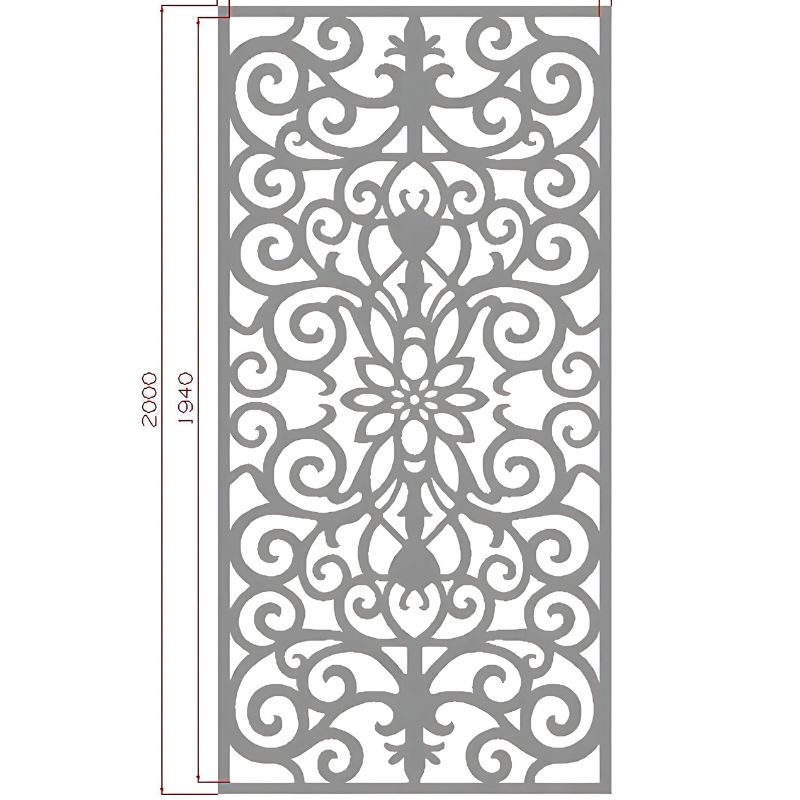

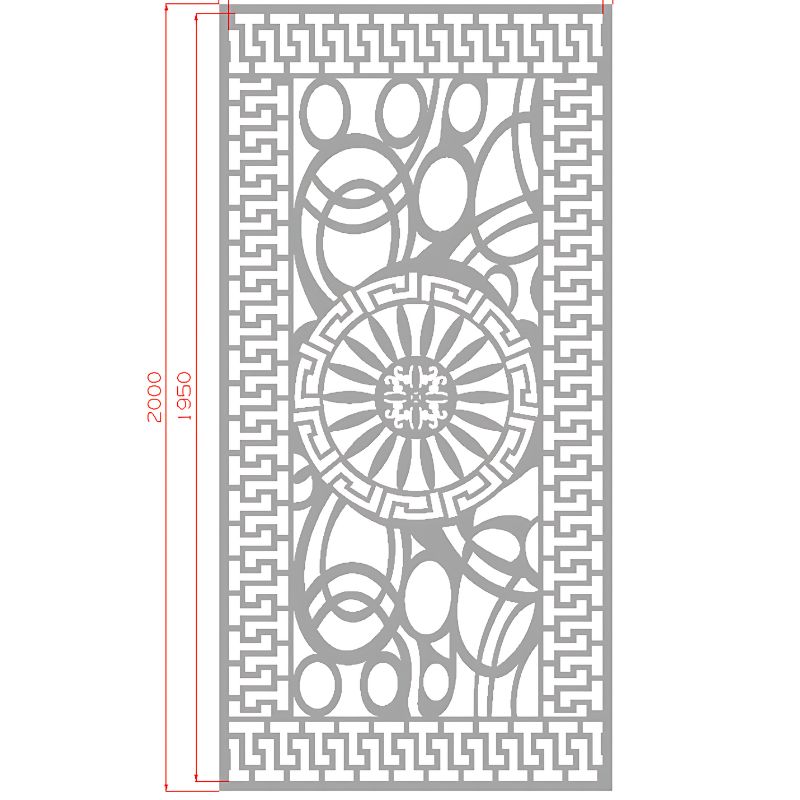

Their defining feature is the ability to produce intricate, repeatable designs with a high degree of precision—whether it’s a geometric lattice, a floral motif, a brand logo, or an abstract art piece.

Benefits of Laser Cut Metal Screens

1. Superior Aesthetic Appeal

Laser cut metal screens transform any surface into an artistic statement, with custom patterns that suit modern, industrial, rustic, or traditional styles. Their three-dimensional depth and play of light and shadow create dynamic visuals that change with the lighting.

2. Customization Without Limits

You’re not limited to standard patterns. Every screen can be custom-designed to your specifications—size, shape, thickness, material, and pattern can all be tailored to reflect your unique style or branding.

3. Exceptional Durability

Laser cut metal screens are made from materials engineered to withstand the elements. Whether exposed to sun, rain, wind, or snow, metals like aluminum and corten steel offer excellent resistance to corrosion and wear.

4. Multi-Purpose Functionality

These screens do more than look good—they provide privacy, security, ventilation, shading, and structural support, all while enhancing the visual identity of the space.

5. Low Maintenance

Metal screens are incredibly easy to maintain. A periodic clean with water and mild soap keeps them looking like new. Powder-coated finishes enhance their longevity and scratch resistance.

Top Applications of Laser Cut Metal Screens

Architectural Facades

Laser cut metal screens offer dramatic facades for residential, commercial, or public buildings. They provide solar shading and climate control while maintaining airflow and adding visual depth.

Privacy Screens and Partition Walls

Create discrete zones in indoor or outdoor spaces without building solid walls. These screens provide visual separation while maintaining an open, airy feel.

Balconies and Railings

Replace conventional railings with beautifully patterned laser cut panels that ensure safety and style. Popular in apartments, hotels, and office complexes.

Garden and Fence Panels

Define garden spaces or secure property lines with corten or aluminum screens that blend art and landscape. These panels withstand weathering while adding decorative flair.

Interior Feature Walls

Use as a focal point in living rooms, lobbies, or hallways. Laser cut wall art panels in stainless steel or aluminum are visually striking and modern.

Gates and Entrances

Make entrances more inviting with bespoke gate panels. Laser cut designs can feature monograms, logos, or patterns that reflect the property’s identity.

Popular Metal Options for Laser Cut Screens

Aluminum

Lightweight, rustproof, and easy to cut with high precision. Ideal for outdoor applications and available in various powder-coated colors.

Corten Steel

Also known as weathering steel, this material develops a natural rust patina over time, protecting it from further corrosion and delivering a rustic, organic look.

Stainless Steel

Sleek, polished, and highly corrosion-resistant, stainless steel is great for high-end indoor or outdoor settings, especially in coastal or humid climates.

Mild Steel

Cost-effective and strong, mild steel is commonly used in interior decorative panels and is often powder-coated to resist rust.

Finishing Options for Metal Screens

Powder Coating

Adds color, texture, and protection. Available in matte, gloss, metallic, and custom color finishes. Powder coating enhances UV resistance and prevents chipping or scratching.

Rust Patina

Corten steel naturally oxidizes into a rich orange-brown surface that provides a protective layer and a bold aesthetic.

Brushed or Polished Finishes

Ideal for stainless steel to achieve a modern, high-gloss or satin finish, suitable for upscale interiors and corporate spaces.

Design Options: Unleashing Creative Potential

We offer a vast design library that includes:

-

Floral Patterns

-

Geometric Shapes

-

Islamic Art and Moroccan Motifs

-

Corporate Logos

-

Nature-Inspired Scenes

-

Custom Typography or Branding

Designs can be scaled to fit any screen size, and custom patterns can be created from client sketches, logos, or architectural plans.

Installation Methods and Support

Our laser cut metal screens are engineered for easy installation across various settings:

-

Wall-mounted with spacers

-

Freestanding frames

-

Integrated into fencing or gate systems

-

Suspended as hanging partitions

-

Bolted or welded into structural supports

Every order includes optional installation hardware and guidance. For complex projects, our technical team is available to provide on-site assistance or detailed CAD drawings.

Industries and Projects We Serve

Our screens are featured in:

-

Luxury residential developments

-

Hotels and resorts

-

Corporate offices and headquarters

-

Urban landscaping and public spaces

-

Museums and cultural centers

-

Retail environments and showrooms

Whether it’s a single decorative screen or an entire building envelope, our team works closely with designers, architects, and contractors to deliver a perfect fit.

casssia@yoyimachinery.com

casssia@yoyimachinery.com