How to Make Wood Grain on Steel Door

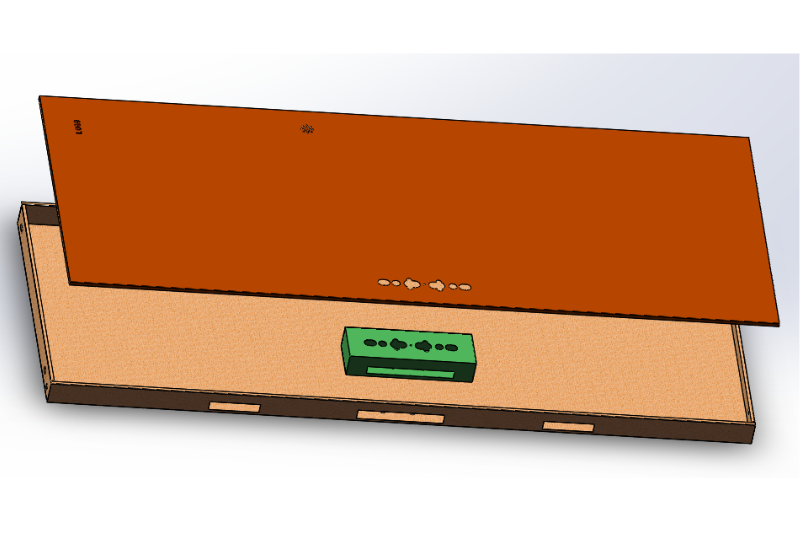

Powder coating wood grain finish is a highly sought-after technique in giving a textured finish to an array of items, such as security doors, steel wooden doors, aluminum profiles, and file cabinets, among others. Currently, there exist two transfer printing processes that are widely utilized to achieve this effect.

The first process, referred to as manual transfer printing, entails applying transfer adhesive onto the workpiece and subsequently bonding the transfer paper onto it. For this method, the transfer paper can be cut into a variety of shapes and pasted in the groove position to achieve an assortment of stitching effects. Thereafter, the workpiece is heated in a powder coating curing furnace to achieve the desired texture.

The second process, known as vacuum transfer printing, relies on a vacuum wood grain effect finish machine. This technique operates by exerting air pressure outside the transfer paper to firmly attach it to the door surface. Compared to manual transfer printing, vacuum transfer printing is a more efficient method that generates clear transfer patterns without the risk of paper sticking. However, this method may cause the phenomenon of missed printing.

Both transfer printing processes are effective in producing a wood grain finish on various products. The choice between these methods depends on factors such as the type of product, the desired finish, and the production requirements.

#door #steeldoor #metaldoor #woodgraindoor #doorsandwindows #metalwork#maindoor #powdercoating #puerta #luxurydoors #securitydoor #steeldoors #doorlock #firedoor #metaldoor #bespokedoors #steeldoors #securitydoor #doorhinges #dveri #mortisehandle #двери