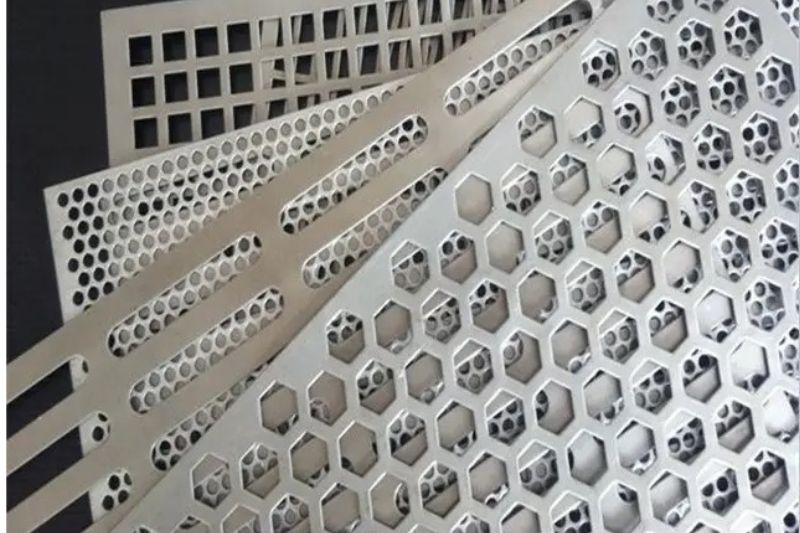

What is a Laser Cut Metal Panel?

A laser cut metal panel is a sheet of metal that has been precisely cut using high-powered laser technology to create intricate patterns, shapes, or designs. These panels offer unmatched accuracy, consistency, and customization, making them highly desirable across a range of industries—from architectural facades to interior decor, privacy screens, industrial components, and signage.

Manufactured from various metals such as aluminum, stainless steel, mild steel, and corten steel, these panels provide both functional utility and aesthetic appeal, adapting to the modern architectural language with ease.

Materials Commonly Used for Laser Cut Panels

Aluminum

-

Lightweight and corrosion-resistant.

-

Ideal for exterior cladding, ceilings, and decorative panels.

-

Easy to paint or powder coat.

Stainless Steel

-

Offers superior strength and resistance to rust.

-

Perfect for kitchens, signage, and high-end decorative elements.

Mild Steel

-

Cost-effective and highly versatile.

-

Frequently used in structural applications and interior partitions.

Corten Steel (Weathering Steel)

-

Develops a rust-like appearance over time.

-

Popular in landscape architecture, garden screens, and outdoor walls.

Popular Applications of Laser Cut Metal Panels

1. Architectural Facades

Laser cut panels provide a visually striking solution for building exteriors. They offer:

-

Sun-shading properties

-

Enhanced building insulation

-

Improved energy efficiency

-

A distinct architectural identity

2. Interior Design

Whether used as room dividers, ceiling panels, or feature walls, laser cut metal adds elegance and texture to modern interiors. It’s frequently featured in:

-

Offices

-

Retail spaces

-

Hotels

-

Residences

3. Privacy Screens and Fencing

Laser cut screens act as functional partitions for both indoor and outdoor settings. They combine:

-

Privacy

-

Ventilation

-

Artistic appeal

4. Decorative Art and Signage

Custom laser cut panels serve as:

-

Company logos

-

Wall-mounted art

-

Wayfinding signs

Their precision and design versatility make them ideal for branding and decor.

5. Railings and Balustrades

Laser cut panels enhance the visual impact of staircases and balconies while meeting safety regulations and providing structural support.

6. Lighting Features

By manipulating light and shadow, these panels create dynamic visual effects. They are used in:

-

Backlit walls

-

Pendant lights

-

Outdoor lighting installations

Customization Options for Laser Cut Panels

-

Thickness: Ranges from ultra-thin (0.8 mm) to heavy-duty (up to 20 mm).

-

Design: Fully customizable based on CAD files, vector drawings, or templates.

-

Finish Options:

-

Powder coating

-

Anodizing

-

Patina finish

-

Polishing

-

-

Mounting Solutions:

-

Wall-mounted

-

Free-standing

-

Hanging or framed systems

-

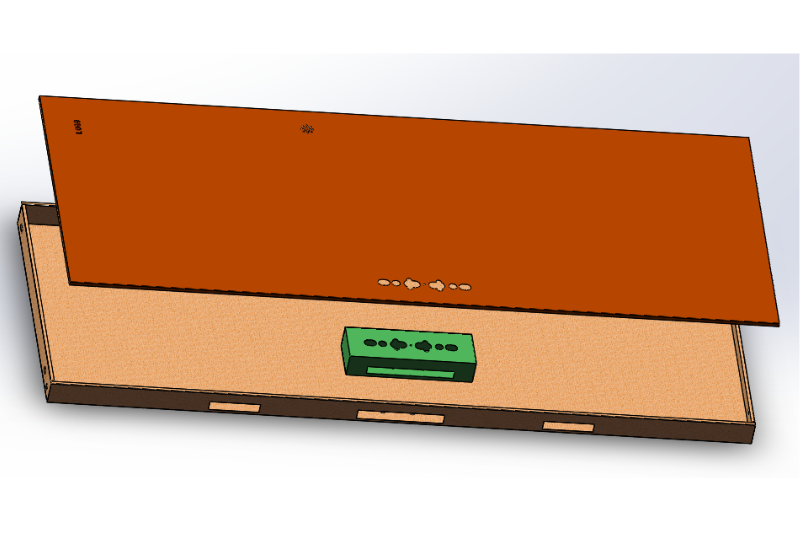

Installation and Integration

Laser cut metal panels can be integrated into various structures and surfaces using:

-

Screw mounting

-

Welded frames

-

Clamping systems

-

Hinged or sliding mechanisms

Whether suspended from ceilings or embedded into masonry, their installation is generally straightforward and adaptable to design needs.

Industries Benefiting from Laser Cut Metal Panels

-

Architecture & Construction

-

Interior Design

-

Retail & Hospitality

-

Landscape Design

-

Corporate Branding

-

Public Infrastructure Projects

Tips for Choosing the Right Panel

-

Define Purpose: Are you aiming for visual enhancement, privacy, safety, or branding?

-

Select Material Wisely: Match the metal to the intended environment (interior vs. exterior).

-

Consider Pattern Complexity: Simpler designs are cost-effective, while intricate patterns add luxury.

-

Ensure Proper Finishing: The right finish enhances both durability and aesthetics.

Conclusion

Laser cut metal panels have transformed the way designers, architects, and engineers approach material aesthetics and function. Their precision, adaptability, and visual impact make them indispensable in modern design and manufacturing landscapes. Whether for architectural beauty, privacy control, or custom branding, these panels provide the perfect union of technology and artistry.