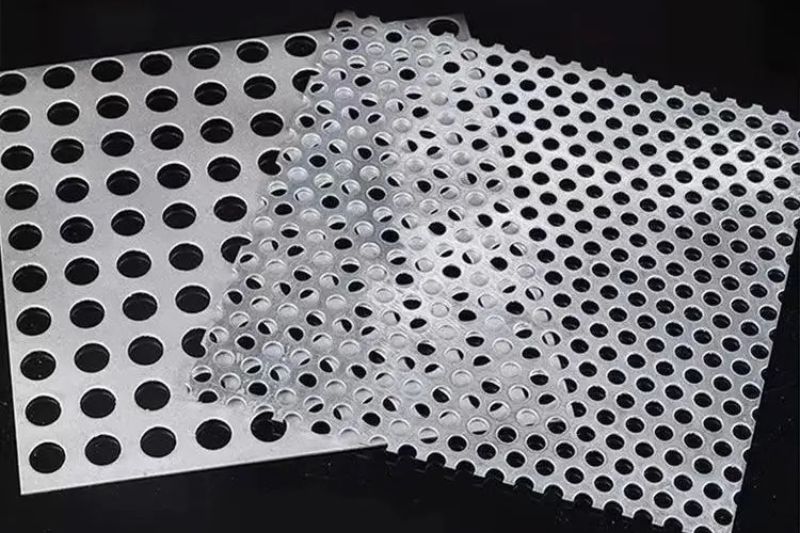

To make a perforated steel sheet, follow these organized steps, incorporating material selection, design, fabrication, and finishing processes:

1. Material Selection

-

Type of Steel: Choose based on application (e.g., stainless steel for corrosion resistance, carbon steel for strength, galvanized steel for cost-effectiveness).

-

Thickness: Determines machinery requirements; thicker sheets need higher tonnage presses.

2. Pattern Design

-

Hole Specifications: Decide shape (round, square, slotted), size, and spacing (pitch). Use CAD software for precision.

-

Layout: Staggered or straight rows; consider open area percentage to balance strength and aesthetics.

-

Tooling Design: Create custom dies/punches aligned with the pattern; CNC programming ensures accuracy.

3. Perforation Process

-

Punch Pressing:

-

Use a hydraulic or mechanical press with a die/punch set. Higher tonnage for thicker steel.

-

CNC-controlled feeding ensures consistent pattern alignment.

-

-

Alternative Methods:

-

Laser Cutting: For intricate designs; higher cost but precise.

-

Drilling: Suitable for small batches or large holes.

-

4. Post-Perforation Processing

-

Deburring: Remove sharp edges via grinding, sanding, or tumbling.

-

Stress Relief: Annealing may be needed if punching induces material stress.

-

Cleaning: Degrease to remove oils/dirt before finishing.

5. Finishing

-

Surface Treatment: Apply coatings (powder coating, galvanizing, painting) for corrosion resistance or aesthetics.

-

Heat Treatment: Optional for hardening or improving material properties.

6. Quality Control

-

Inspection: Verify hole dimensions, spacing, and sheet flatness using calipers, optical tools, or laser scanners.

-

Testing: Conduct structural tests (e.g., load-bearing) if required.

7. Cutting to Size

-

Use shearing, laser, or waterjet cutting to achieve final dimensions.

8. Packaging and Shipping

-

Protect sheets with anti-rust coatings/packaging materials to prevent damage during transit.