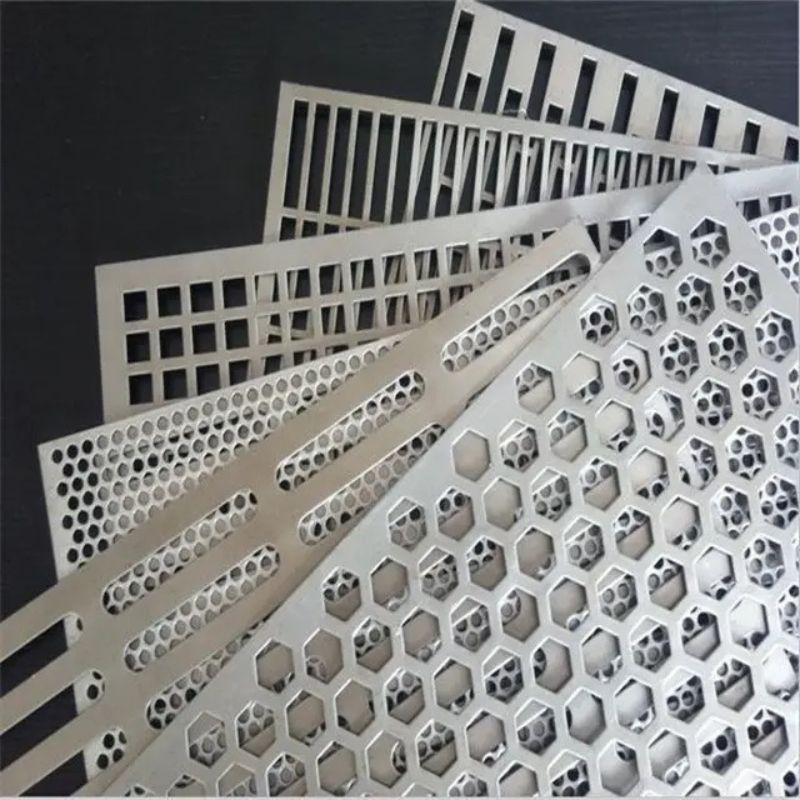

Introduction to Square Hole Perforated Metal Sheet

أ square hole perforated metal sheet is a highly versatile material created by punching uniform square holes into a solid metal sheet. With its geometric consistency and symmetrical appearance, this type of perforated sheet offers a unique combination of aesthetic value, superior airflow, and structural integrity. It is widely used in industries ranging from architecture and construction to machinery, retail, and agriculture.

Available in materials like mild steel, stainless steel, galvanized steel, aluminum, and even brass, square hole perforated sheets can be tailored to meet precise engineering or design specifications.

Top Benefits of Square Hole Perforated Metal Sheet

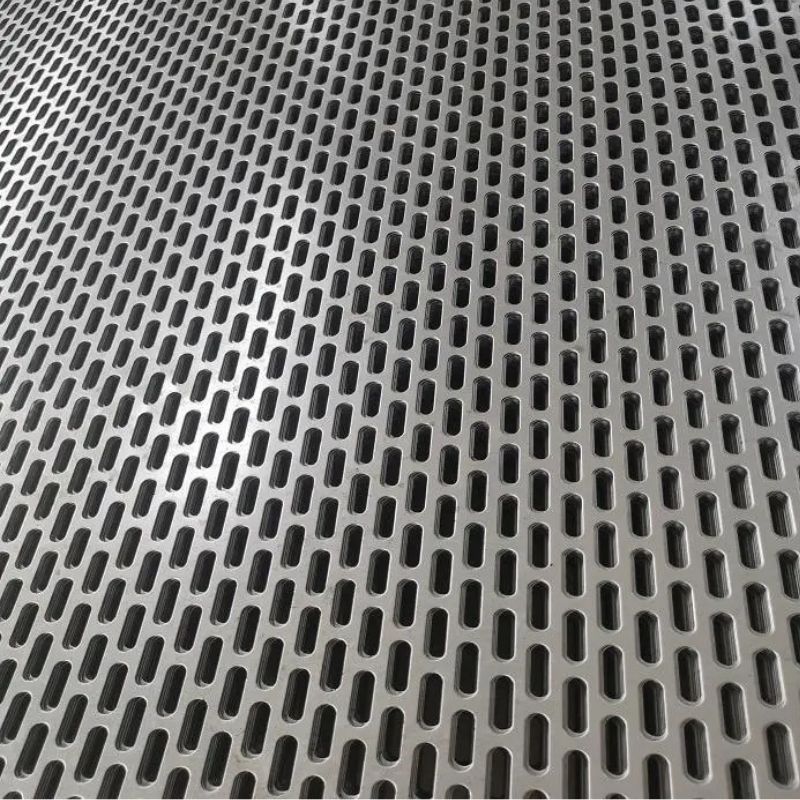

1. High Open Area for Maximum Flow Efficiency

Square perforations provide larger open areas compared to round or slotted holes of the same pitch. This allows for:

-

Improved airflow and ventilation

-

Better light transmission

-

Efficient drainage and filtration

-

Superior acoustic performance

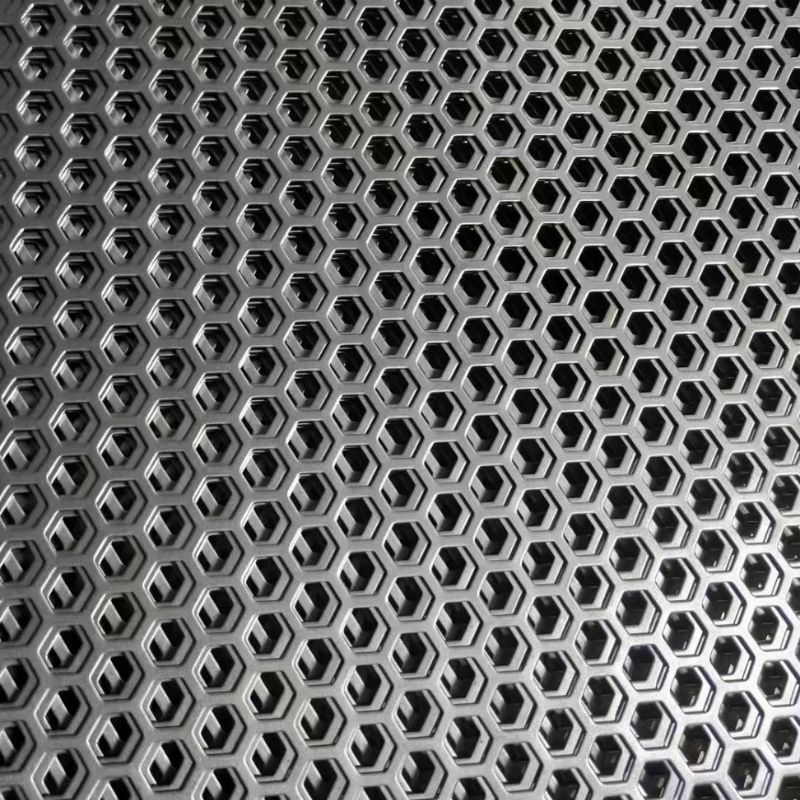

2. Clean and Modern Aesthetic

With its uniform and angular design, square hole perforated metal is visually striking. It provides a sleek, clean, and contemporary look, making it a preferred choice for architectural cladding, interior design, and modern facades.

3. Excellent Strength and Stability

Square hole perforated sheets maintain excellent load-bearing capacity and structural integrity, even in larger open areas. This makes them suitable for protective barriers, machine guards, and industrial enclosures.

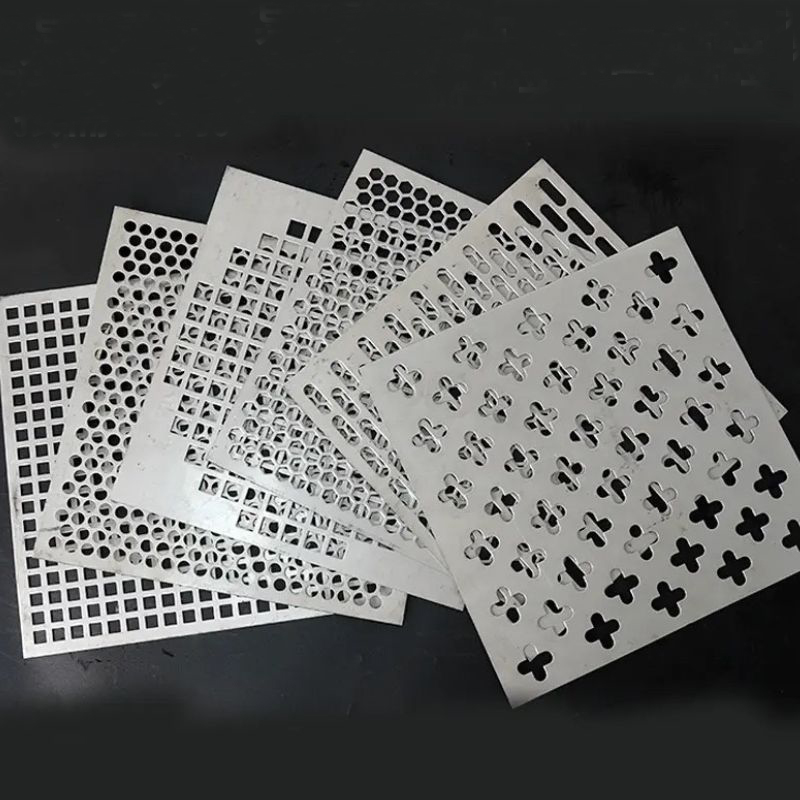

4. Versatility in Pattern and Configuration

Square perforations can be arranged in:

-

Straight-line grids for symmetry and simplicity

-

Staggered layouts for aesthetic or strength optimization

This flexibility enables creative freedom and practical adaptation across many fields.

Key Applications of Square Hole Perforated Metal Sheets

1. Architectural and Decorative Applications

Square hole perforated metal sheets are extensively used in building design, including:

-

Exterior facades and cladding

-

Interior partitions and wall panels

-

Ceiling panels and ventilation screens

-

Balustrades and privacy screens

They offer the perfect blend of functionality and design appeal.

2. Industrial and Mechanical Engineering

In industrial environments, square perforated sheets are vital for:

-

Machinery covers and guards

-

Filtration and separation units

-

Storage racks and sorting bins

-

Processing equipment screens

Their design ensures strong airflow and debris control.

3. Retail Displays and Commercial Fixtures

Retailers use square perforated sheets for:

-

Display panels

-

Shelving units

-

Product organizers

-

Storefront design elements

Their visual clarity and customizable nature make them ideal for high-visibility commercial spaces.

4. Agricultural and Food Processing

Due to their smooth, easy-to-clean surfaces, square hole sheets are used in:

-

Seed and grain sieving systems

-

Drying trays

-

Ventilated storage bins

-

Sorting and washing equipment

Stainless steel variants are preferred for hygiene and corrosion resistance.

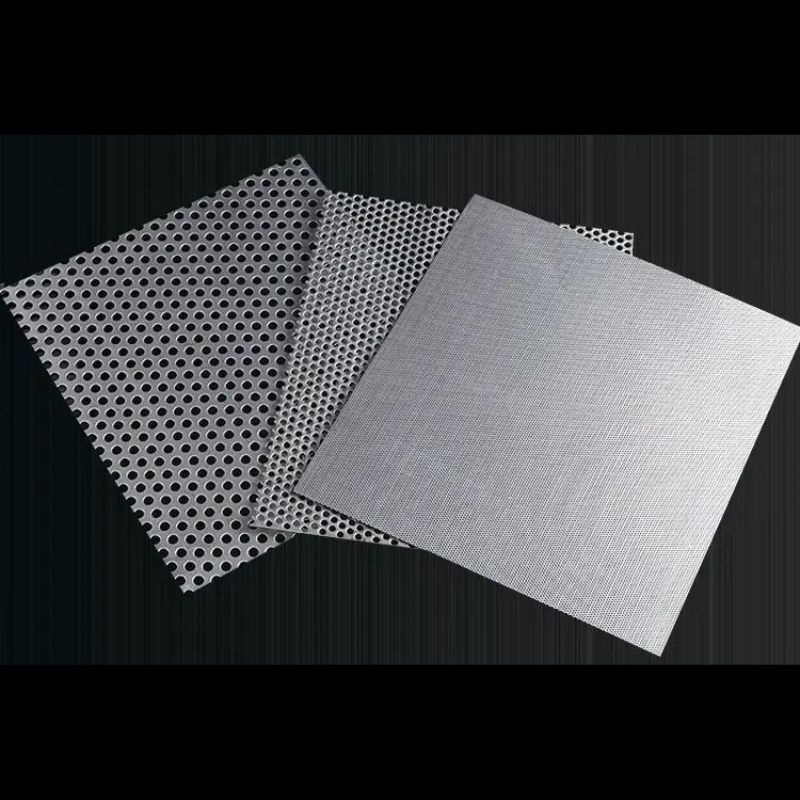

Common Materials Used in Square Hole Perforated Sheets

1. Stainless Steel

-

Excellent for corrosive and sanitary environments

-

Available in grades such as 304 and 316

-

Ideal for medical, food, and marine applications

2. Galvanized Steel

-

Economical and corrosion-resistant

-

Perfect for outdoor, agricultural, and utility purposes

3. Mild Steel

-

Strong and cost-effective

-

Can be painted, powder-coated, or plated

-

Suitable for interior and mechanical applications

4. Aluminum

-

Lightweight and rust-resistant

-

Used in aerospace, decorative, and architectural uses

5. Brass and Copper

-

Decorative and antimicrobial

-

Commonly used in high-end interior design, ventilation grilles, and artistic applications

Pattern Specifications and Customization

Hole Size and Spacing

-

Hole sizes typically range from 2mm to 50mm or more

-

Spacing (pitch) is the distance between hole centers and is often matched to specific airflow or design requirements

-

أ higher open area percentage enhances airflow and reduces weight

Sheet Thickness

Square hole perforated sheets come in various thicknesses, commonly from 0.5mm to 6mm, but can be custom-ordered for heavier applications.

Standard vs. Custom Layouts

Manufacturers offer:

-

Straight row patterns: Ideal for functional applications

-

Staggered square layouts: Provide more aesthetic appeal

-

Fully customized designs: For branding or artistic use

Surface Finishes and Treatments

To enhance appearance and longevity, perforated sheets can undergo various finishing processes:

-

Powder coating for color and protection

-

Electropolishing for a smooth, shiny surface

-

Hot-dip galvanizing for outdoor corrosion resistance

-

Brushing or polishing for interior aesthetic applications

-

Anodizing (for aluminum) to improve durability and corrosion resistance

What to Consider When Buying

Before purchasing, evaluate the following:

-

Purpose of use: Functional or decorative?

-

Material selection: Based on environment and load

-

Hole size and open area: Determines flow rates and visibility

-

Sheet thickness: Impacts strength and weight

-

Finish requirements: Aesthetic vs protective

-

Customization needs: Branding, patterns, specific dimensions

casssia@yoyimachinery.com

casssia@yoyimachinery.com