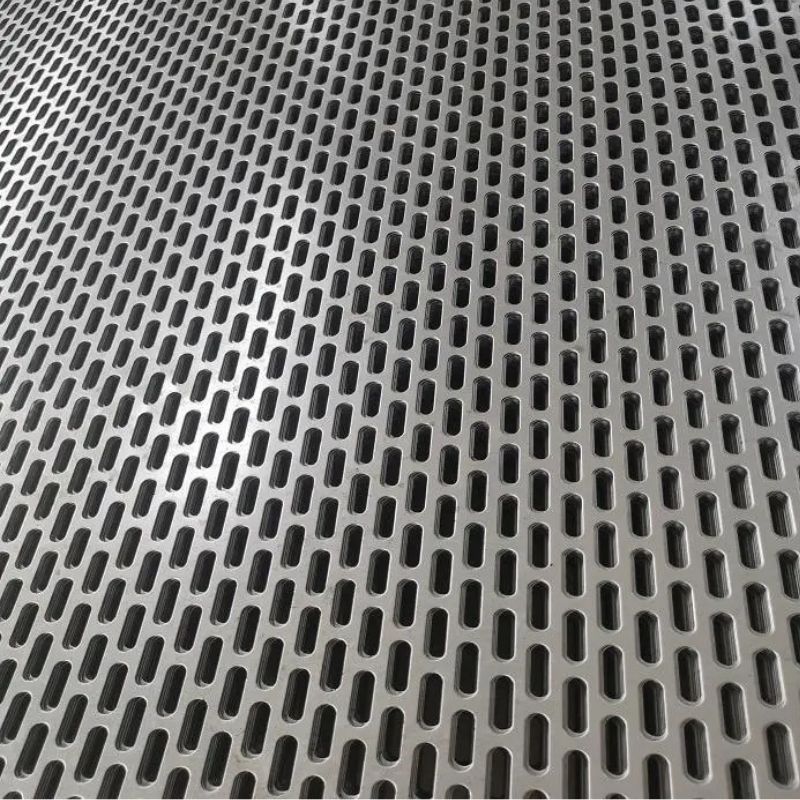

Introduction to Slot Hole Perforated Sheet

А slot hole perforated sheet is a specialized metal sheet designed with elongated holes (slots) arranged in uniform patterns. These sheets are manufactured by precision punching or laser-cutting to produce slots of varying widths and lengths, providing a highly functional and aesthetically flexible solution across numerous industries.

Used in filtration, screening, architectural design, and industrial machinery, slot hole perforated sheets offer unique benefits that make them an essential material in both form and function.

Key Benefits of Slot Hole Perforated Sheets

1. Directional Flow Control

Unlike round or square holes, slot holes allow for directional air, light, or liquid flow. This makes them ideal for:

-

Ventilation panels

-

Drainage systems

-

Acoustic screens

-

Material sorting and separation

The elongated design allows for greater control over the flow direction and speed.

2. Enhanced Open Area

Slot perforations provide a larger open area percentage compared to round holes of similar width, enabling:

-

Improved material throughput

-

Superior drainage and filtration

-

Higher efficiency in acoustic panels

This is particularly useful in industries like food processing, mining, and HVAC systems.

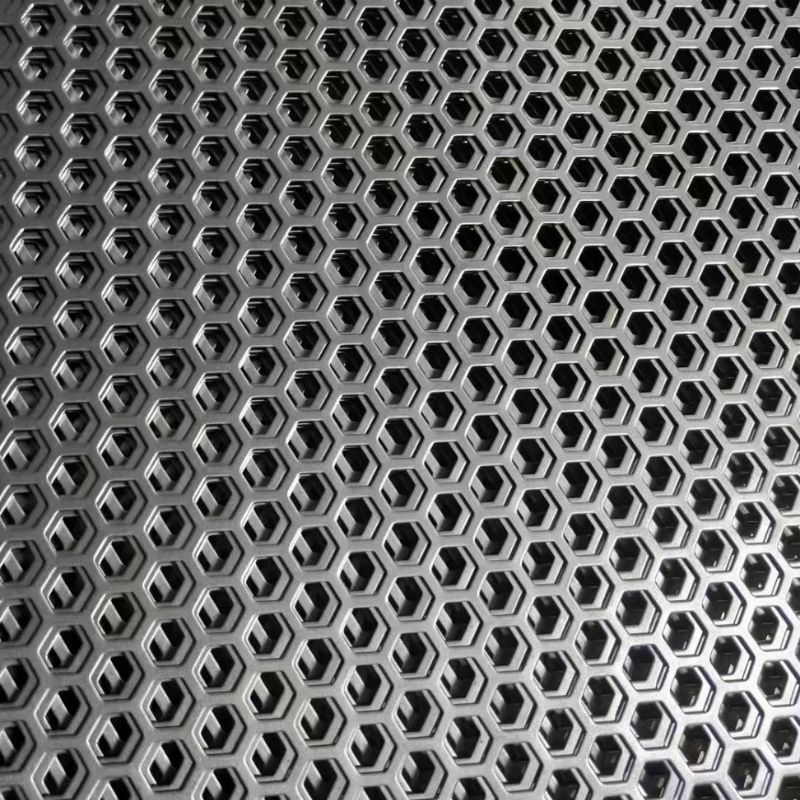

3. Modern and Distinctive Aesthetic Appeal

Slot holes offer a sleek, linear design that creates a striking visual impact. Designers and architects choose slotted sheets for:

-

Wall cladding and partitions

-

Ceiling panels and sunscreens

-

Urban furniture and public installations

They offer clean lines and a contemporary style, enhancing the visual dynamics of any space.

4. Structural Integrity and Strength

Despite their open design, slot perforated sheets maintain excellent mechanical strength, particularly when oriented strategically. They are used in applications requiring:

-

Durability under dynamic loads

-

Resistance to wear and tear

-

Long-term structural reliability

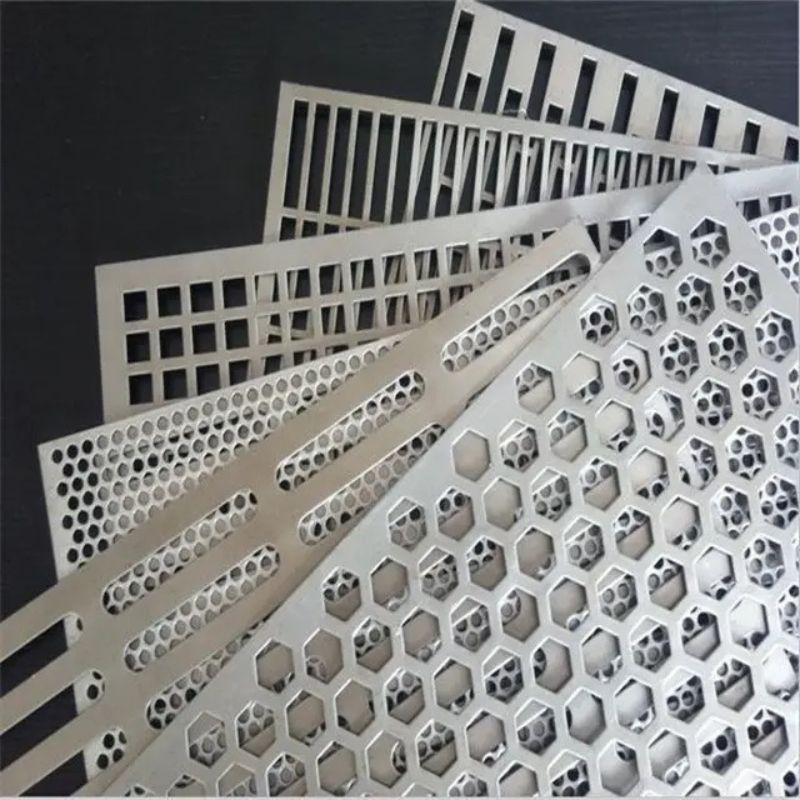

Common Applications of Slot Hole Perforated Sheets

1. Industrial and Mechanical Applications

Slot hole sheets are widely used in:

-

Sorting and grading machinery

-

Material drying and draining trays

-

Protective guards and safety enclosures

-

Vibration screening systems

Their elongated slots optimize material flow and minimize clogging, making them ideal for tough environments.

2. Architectural and Interior Design

Designers use slotted sheets for:

-

Sunshades and louvered facades

-

Ventilation grilles

-

Room dividers and decorative panels

-

Acoustic wall linings

They provide privacy, shading, and acoustic control while maintaining a sleek, modern appearance.

3. Agricultural and Food Processing

Slot hole perforated sheets are highly effective for:

-

Washing and draining trays

-

Grain and seed separators

-

Drying equipment components

-

Livestock ventilation panels

They support high-efficiency processing with excellent hygiene standards, especially in stainless steel options.

4. Automotive and Transport Systems

In transportation sectors, these sheets are used for:

-

Engine and radiator guards

-

Airflow control systems

-

Acoustic insulation layers

-

Protective panels and grilles

The directional nature of slot holes helps optimize cooling and sound reduction.

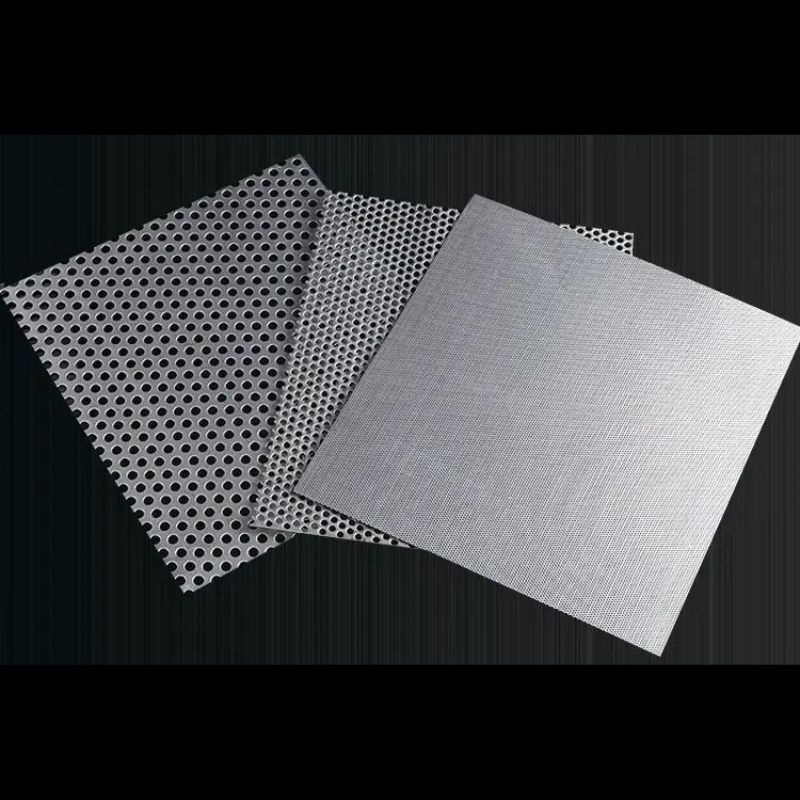

Materials Used in Slot Hole Perforated Sheets

1. Stainless Steel (304, 316)

-

Superior corrosion resistance

-

Hygienic and durable

-

Ideal for food, medical, and marine applications

2. Galvanized Steel

-

Zinc-coated for corrosion protection

-

Suitable for outdoor and industrial environments

-

Economical with good structural performance

3. Aluminum

-

Lightweight and rust-resistant

-

Easy to fabricate and install

-

Common in architectural and transport uses

4. Mild Steel

-

Strong and cost-effective

-

Easily coated or painted

-

Used in mechanical and structural applications

Slot Configurations and Specifications

Slot Sizes

Slot hole perforations vary in:

-

Длина: Commonly between 10mm to 100mm

-

Ширина: Ranges from 1mm to 20mm

Sizes can be customized to suit:

-

Specific airflow rates

-

Filtration requirements

-

Aesthetic preferences

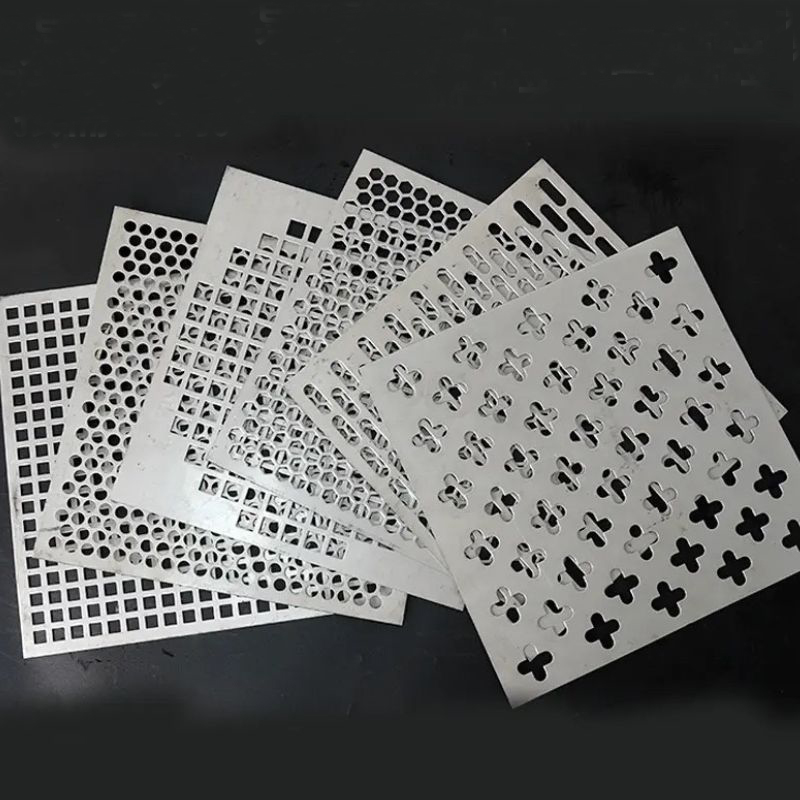

Hole Orientation

-

Straight slot layout: Slots are aligned in straight, parallel lines. Ideal for visual uniformity.

-

Staggered slot layout: Offers increased strength and a more dynamic look.

-

Diagonal layouts: Provide unique visual effects and directional airflow.

Sheet Thickness

Standard thicknesses range from 0.5mm to 6mm, depending on application needs. Heavier gauges are used for load-bearing or heavy-duty applications.

Finishing Options

Slot hole perforated sheets can be enhanced with the following surface treatments:

-

Powder coating: For added color and corrosion resistance

-

Anodizing: Especially for aluminum sheets, adds strength and color options

-

Polishing/Brushing: For architectural aesthetics

-

Galvanizing: Provides long-lasting protection in corrosive environments

Customization Capabilities

Manufacturers often provide full customization services:

-

Custom slot lengths, widths, and spacings

-

Tailored sheet dimensions

-

CNC laser cutting for precise patterns

-

Forming, folding, and welding for final assemblies

This makes slot hole sheets a go-to material for bespoke engineering and design projects.

Installation and Maintenance Tips

-

Use protective handling to avoid injury from sharp edges

-

Align slots correctly for intended airflow or visual direction

-

Clean regularly to prevent buildup in slot areas

-

Apply rust-inhibiting finishes in outdoor environments

Maintenance depends on the material type and application environment.

Buying Considerations

When selecting a slot hole perforated sheet, consider:

-

Purpose: Filtration, ventilation, decoration, or protection?

-

Материал: Will it be exposed to moisture, chemicals, or heat?

-

Slot dimensions and layout: Determine flow rate and aesthetic

-

Sheet thickness: Balance between weight and strength

-

Finishing needs: Coated, painted, or untreated?

-

Customization: Do you require unique patterns or assembly?

casssia@yoyimachinery.com

casssia@yoyimachinery.com