Что такое перфорированная металлическая сетка?

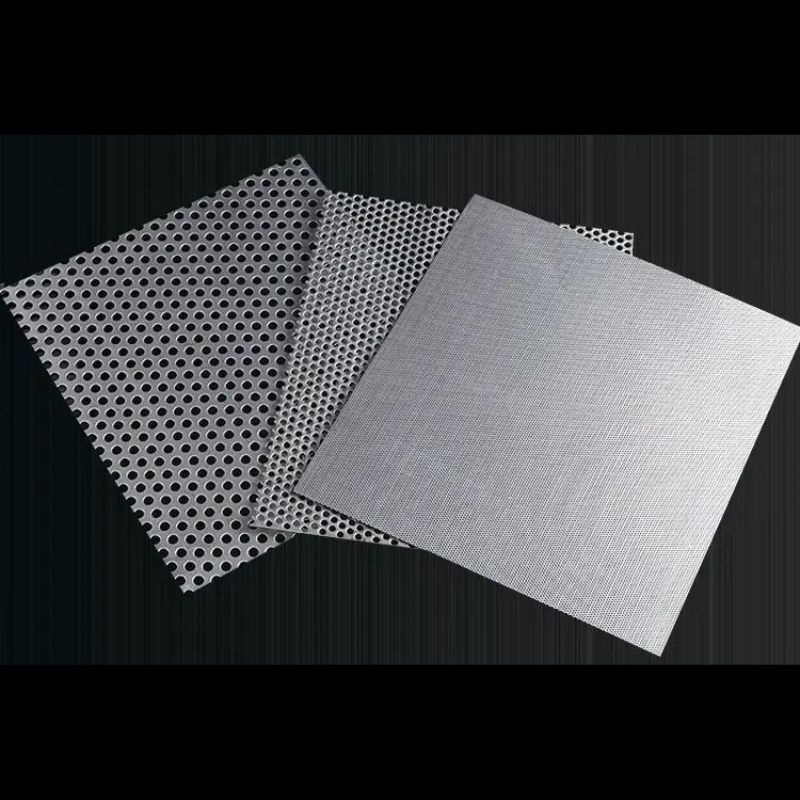

Перфорированная металлическая сетка относится к листам металла, которые были механически или вручную пробитые отверстия или узоры для создания сетчатой структуры. Она сочетает в себе долговечность и прочность цельного металла с гибкость и функциональность сетки. Доступно в различных материалах, таких как нержавеющая сталь, оцинкованная сталь, алюминий, медь и латуньПерфорированная металлическая сетка является важнейшим компонентом в промышленном, архитектурном и коммерческом секторах.

Почему стоит выбрать перфорированную металлическую сетку?

1. Непревзойденная сила и долголетие

В отличие от тканевой или пластиковой сетки, Перфорированная металлическая сетка предназначена для выдерживания интенсивного износа, экстремальных температур и воздействия окружающей среды.. Он устойчив к коррозии, ударам и деформации, обеспечивая долгосрочная структурная целостность.

2. Точный контроль потока воздуха и света

Перфорация в металлической сетке позволяет контролируемая циркуляция воздуха, отвод воды и фильтрация света. Это делает его идеальным для системы вентиляции, солнцезащитные устройства и звукопоглощающие панели.

3. Функциональная и эстетическая привлекательность

С различные размеры, формы и узоры отверстий, перфорированную сетку можно адаптировать для смешивания функциональность с современным дизайном. Он часто используется в архитектурные фасады, элементы дизайна интерьера и художественные инсталляции, придавая элегантный современный вид.

4. Экологически устойчивый

Сделано из полностью перерабатываемые металлы, перфорированная металлическая сетка способствует экологически чистые методы строительства и производства. Он поддерживает сертификация LEED и другие стандарты зеленого строительства.

Основные области применения перфорированной металлической сетки

1. Архитектурное проектирование и фасады зданий

Перфорированная металлическая сетка пользуется популярностью в современной архитектуре благодаря своей способности баланс эстетики и функциональности. Приложения включают в себя:

-

Солнцезащитные навесы и жалюзи

-

Декоративные фасады и облицовка

-

Потолки и перегородки

-

Акустические панели

Он обеспечивает тепловая эффективность, конфиденциальность и яркая архитектурная индивидуальность.

2. Промышленное и механическое использование

Отрасли промышленности используют перфорированную металлическую сетку для своих целей. устойчивость и адаптивность. Распространенные области применения:

-

Защитные ограждения и кожухи для машин

-

Системы фильтрации воздуха и жидкости

-

Акустические шумоизолирующие барьеры

-

Операции просеивания и сортировки

Его высокое соотношение прочности к весу позволяет ему работать в условиях сложные условия эксплуатации.

3. Приложения для обеспечения безопасности

Перфорированная сетка служит эффективным защитный барьер в:

-

Ограждения и ворота

-

Оконные сетки и двери

-

Лестничные ограждения и перила

Он предлагает улучшенная видимость и воздушный поток без ущерба для безопасности.

4. Автомобили и транспорт

В автомобильной технике, легкая и устойчивая к коррозии перфорированная металлическая сетка улучшает как производительность, так и эстетику:

-

Решетки радиатора

-

Тепловые экраны

-

Вентиляционные панели

-

Крышки динамиков

Его использование поддерживает снижение веса транспортного средства и терморегуляция.

5. Сельскохозяйственная и пищевая промышленность

Перфорированная структура позволяет легкая очистка и устойчивость к накоплению бактерий, что имеет важное значение в таких пищевых приложениях, как:

-

Сушильные стеллажи

-

Сортировка и мойка лотков

-

Фильтры для зерна и семян

В таких условиях особенно предпочтительна сетка из нержавеющей стали.

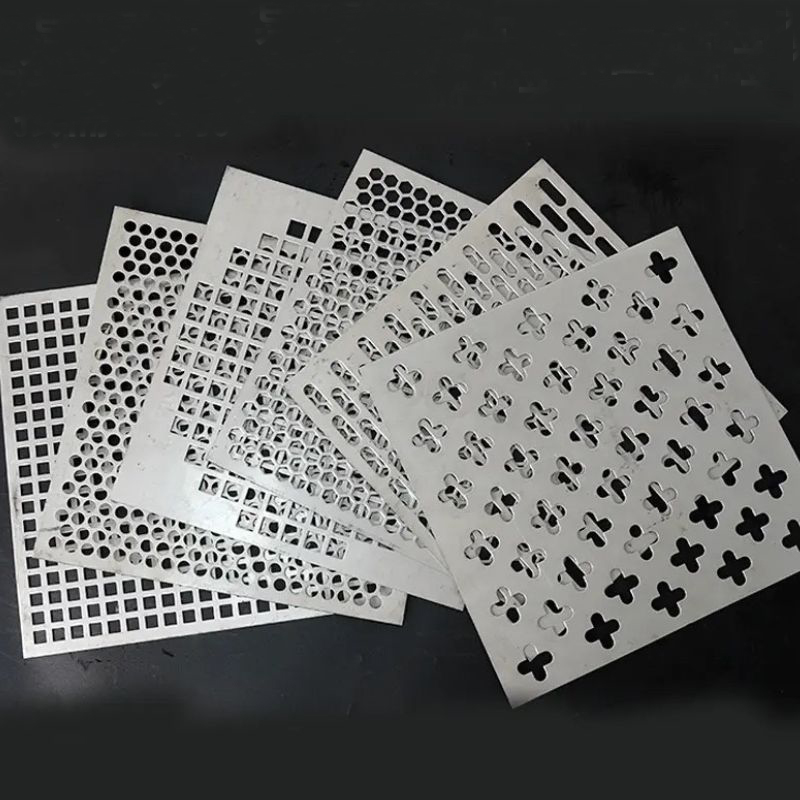

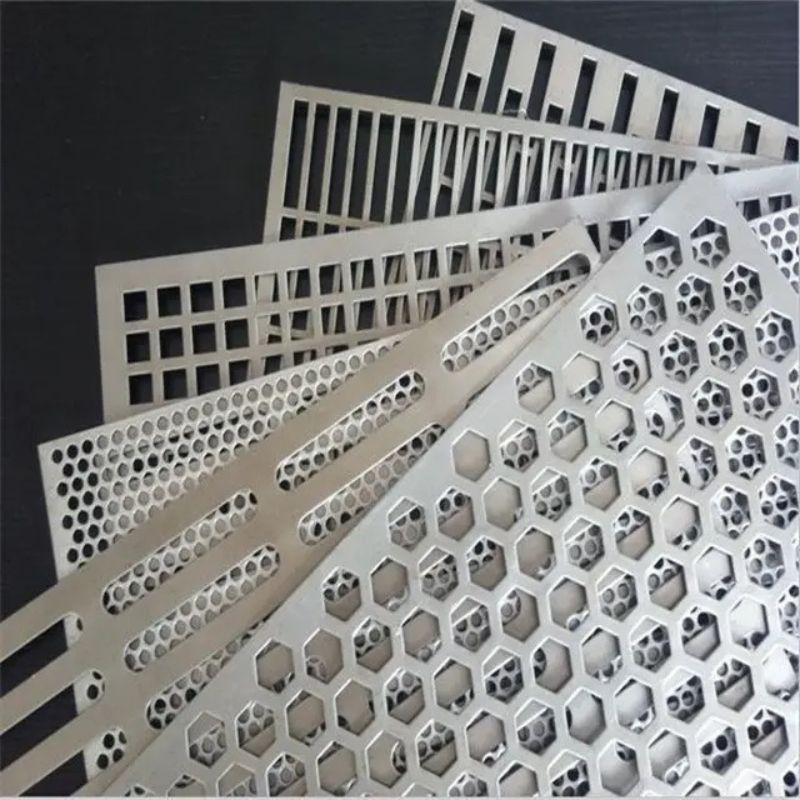

Типы перфорации в металлической сетке

1. Круглые отверстия

Круглые отверстия Наиболее распространены и эффективны для оптимизации открытых пространств. Подходит для:

-

Вентиляция

-

Скрининг

-

Декоративные цели

2. Квадратные отверстия

Квадратные перфорации обеспечивают чистый, геометрический вид и идеально подходят для:

-

Розничные дисплеи

-

Фехтование

-

Архитектурные приложения

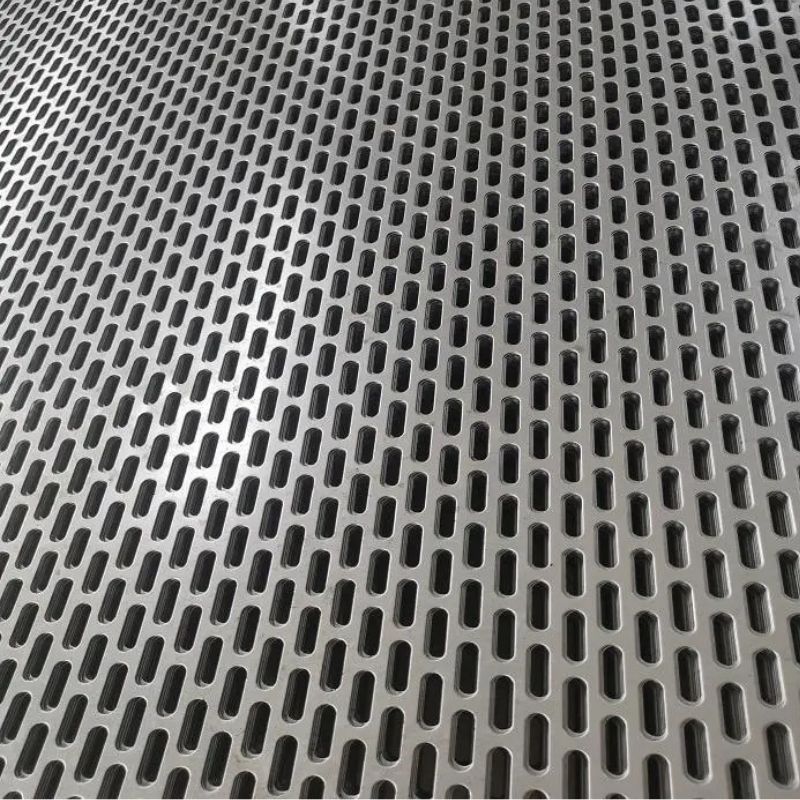

3. Продолговатые и прямоугольные отверстия

Прорезные отверстия позволяют направленный поток материалов Например, при просеивании или сливе. Они полезны для:

-

Промышленная переработка

-

Операции сушки

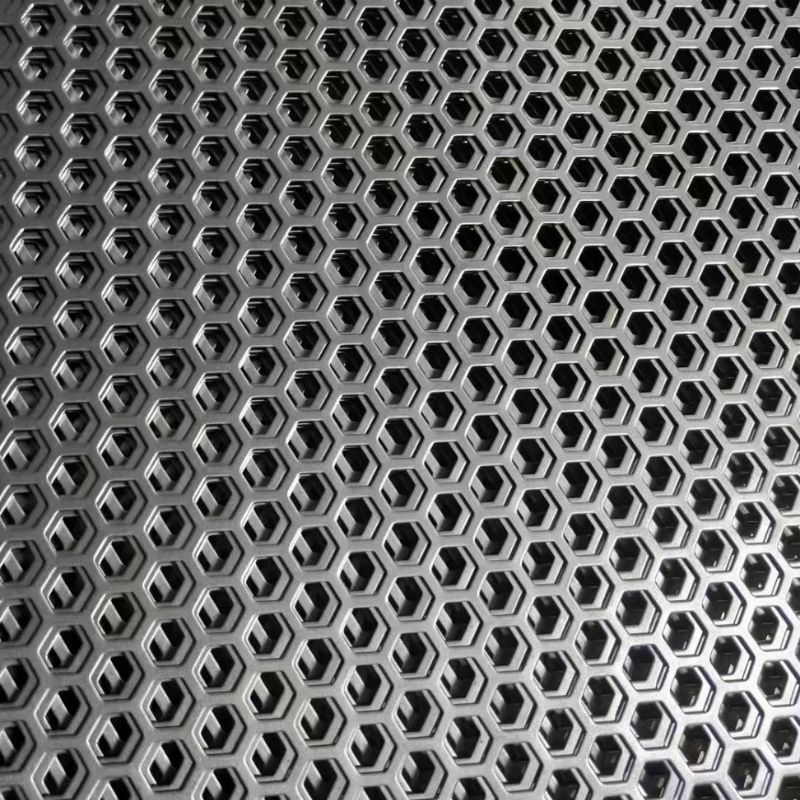

4. Шестиугольные и индивидуальные узоры

Эти модели улучшают визуальная привлекательность при сохранении прочности и воздухопроницаемости. Они широко используются в:

-

Архитектурная облицовка

-

Индивидуальный дизайн интерьера

Доступные материалы для перфорированной металлической сетки

1. Нержавеющая сталь

Высокая устойчивость к коррозия, тепло и химикаты, идеально подходит для:

-

Гигиеническая среда

-

Морские и прибрежные применения

-

Медицинское и пищевое применение

2. Оцинкованная сталь

Предложения защита от ржавчины по доступной цене. Отлично подходит для:

-

Наружные установки

-

Ограждения и ограждения

3. Алюминий

Легкая, но прочная алюминиевая сетка идеально подходит для:

-

Потолки и декоративные панели

-

Системы вентиляции

Он также обладает естественной устойчивостью к коррозии.

4. Латунь и медь

Они предлагают декоративная отделка и антимикробные свойства, что делает их подходящими для:

-

Акценты интерьера

-

Элитные торговые площади

-

Общественные здания

Варианты изготовления на заказ

Для удовлетворения различных потребностей производители предлагают индивидуальные услуги перфорации и отделки, включая:

-

Индивидуальные размеры отверстий, формы и расстояния

-

Панели, вырезанные по размеру

-

Фальцовка, сварка и обработка поверхностей

-

Порошковое покрытие или анодирование

Эти параметры настройки позволяют клиентам достичь как технических, так и дизайнерских целей эффективно.

Преимущества перед альтернативными материалами

-

Более высокая прочность, чем у пластиковой сетки

-

Лучшая устойчивость к огню и погодным условиям

-

Превосходная несущая способность

-

Полностью пригоден для вторичной переработки и не требует особого ухода

Это делает перфорированная металлическая сетка — более экологичный и экономичный выбор в долгосрочной перспективе.

Факторы, которые следует учитывать перед покупкой

При выборе перфорированной металлической сетки оцените:

-

Тип материала на основе воздействия окружающей среды

-

Расположение и размер отверстий в соответствии с потребностями в потоке воздуха или фильтрации

-

Толщина и вес листа для структурных требований

-

Процент открытой площади для видимости или пропускания света

-

Чистота поверхности для соответствия эстетическим требованиям или требованиям коррозионной стойкости

Всегда приобретайте продукцию у проверенных поставщиков, чтобы гарантировать точность изготовления и стабильное качество.

Заключение

Перфорированная металлическая сетка — это высокопроизводительный, многофункциональный материал, который служит широкому спектру целей — от архитектурное проектирование для промышленной фильтрации. С безграничные возможности настройки и исключительная долговечность, он по-прежнему остается лучшим выбором для инженеров, архитекторов и производителей.

casssia@yoyimachinery.com

casssia@yoyimachinery.com