Introduction to Hollow Metal Doors

What are Hollow Metal Doors?

Hollow metal doors are a popular choice for commercial, industrial, and institutional applications. They are made of steel or stainless steel and consist of an outer metal shell filled with an insulating core. The insulating core can be made of different materials, such as foam, honeycomb, or mineral wool, depending on the desired performance characteristics.

Hollow Metal Door Structure:

Hollow metal doors are widely used in commercial and industrial applications due to their durability, security, and fire resistance. Understanding the structure of a hollow metal door is essential to appreciate its benefits and functionality. Here’s a breakdown of the main components of a hollow metal door structure:

I. Door Panels

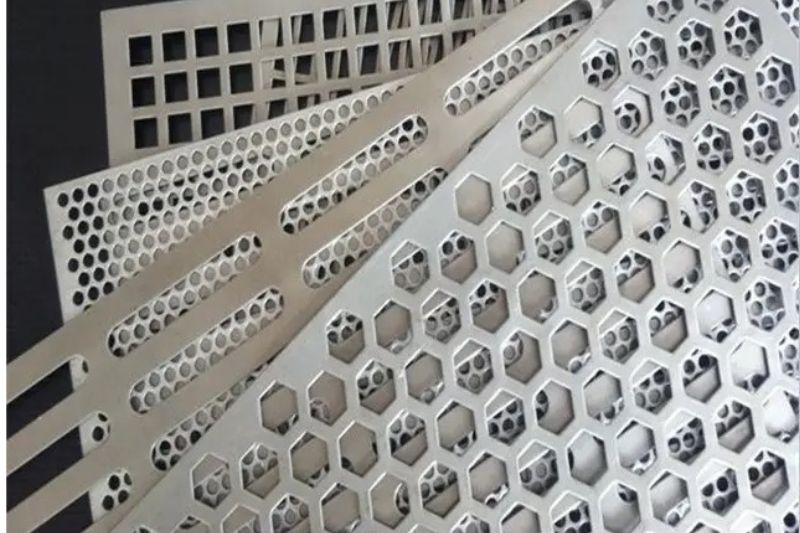

- Outer steel sheets: Hollow metal doors consist of two outer steel sheets that form the front and back faces of the door. These sheets are typically made of galvanized or stainless steel and provide strength, rigidity, and resistance to corrosion.

- Panel designs: The outer steel sheets may have different panel designs, such as flush (flat and smooth) or embossed with decorative patterns. These designs can enhance the door’s aesthetic appeal and provide additional rigidity.

II. Door Core

- Insulating core: The space between the outer steel sheets is filled with an insulating core material, such as honeycomb kraft paper, polystyrene, or polyurethane foam. This core material provides thermal insulation, sound attenuation, and structural support to the door.

- Reinforcements: The door core may also include steel reinforcements or stiffeners to increase its strength and rigidity. These reinforcements are strategically placed within the core to support hardware components, such as locks and hinges.

III. Door Frame

- Frame components: The hollow metal door is supported by a metal frame, typically made of galvanized or stainless steel. The frame consists of components such as head, jamb, and sill sections that are shaped and welded or mechanically joined to form a rigid structure.

- Anchoring and reinforcement: The frame is anchored to the surrounding wall structure using suitable fasteners and may also include reinforcement plates or channels for added strength and stability.

IV. Door Hardware

- Hinges: Hollow metal doors are equipped with heavy-duty hinges that support the door’s weight and ensure smooth operation. These hinges are typically made of steel or brass and are designed for high-traffic and high-use applications.

- Locks and latches: To provide security, hollow metal doors include locks and latches that are compatible with the door’s design and intended use. These may include mortise locks, cylindrical locks, or exit devices, depending on the specific application and security requirements.

- Closers and operators: Door closers or operators are installed on hollow metal doors to control the opening and closing speed and ensure the door closes securely. These devices can be manual or automatic, depending on the specific needs of the application.

- Other hardware: Additional hardware components, such as push and pull handles, kick plates, or door stops, may be installed on hollow metal doors to enhance their functionality and appearance.

V. Weatherstripping and Seals

- Weatherstripping: To improve energy efficiency and prevent drafts, hollow metal doors are fitted with weatherstripping materials along the edges of the door and frame. These materials, such as gaskets or brush seals, create a tight seal when the door is closed.

- Thresholds: A metal threshold is installed at the bottom of the door opening to create a seal between the door and the floor. This component helps prevent drafts, water infiltration, and the passage of pests or debris.

Benefits of Hollow Metal Doors:

Security and Durability

One of the main advantages of hollow metal doors is their strength and durability. They are resistant to impacts, forced entry, and corrosion, making them an ideal choice for high-security applications. Additionally, metal doors typically have a longer lifespan compared to their wooden counterparts.

Energy Efficiency

Hollow metal doors can help improve a building’s energy efficiency, as their insulating core reduces heat transfer. This feature can help lower energy costs by maintaining consistent temperatures inside the building, regardless of the weather conditions outside.

Fire Resistance

Many hollow metal doors have fire-resistant properties, which can help slow the spread of fire and smoke in the event of a fire. They can be designed to meet specific fire-rating requirements, ensuring that they provide the necessary protection for a given application.

Customization and Aesthetics

Hollow metal doors can be customized to suit various design preferences and functional requirements. They can be painted or coated in a wide range of colors and finishes, and can even be designed to mimic the appearance of wood, if desired. Additionally, these doors can be fitted with windows, louvers, or other features to enhance their appearance and functionality.

Applications of Hollow Metal Doors:

Commercial Buildings

Hollow metal doors are commonly used in commercial buildings, such as offices, retail spaces, and hotels. Their durability, security, and fire resistance make them an ideal choice for these environments.

Industrial Facilities

Industrial facilities, including factories and warehouses, benefit from the strength and wear resistance that hollow metal doors offer. These doors can endure harsh conditions common in industrial settings, making them a practical choice for maintaining safety and security.

Public Institutions

Public institutions, like schools, hospitals, and government buildings, also gain advantages from using hollow metal doors. In these spaces, the doors’ durability, fire resistance, and energy efficiency are essential factors that contribute to occupants’ safety and well-being.

Installation and Maintenance:

Installation Process

Proper installation of hollow metal doors is crucial for ensuring their performance and longevity. The process generally involves the following steps:

- Measure the door opening to confirm the correct door size is selected.

- Prepare the door frame by installing anchors and leveling it within the opening.

- Attach the hinges to the door leaf and frame.

- Install the door leaf into the frame, ensuring it is properly aligned and swings smoothly.

- Install hardware components, such as handles, locks, and closers.

- Adjust and fine-tune the door to guarantee proper operation and sealing.

Maintenance Tips

Regular maintenance is necessary for keeping hollow metal doors functioning optimally and maintaining their appearance. Here are some tips for taking care of your hollow metal doors:

Cleaning and Inspection

Clean the door and its components regularly using a mild detergent and water. Avoid using abrasive cleaners or materials that could damage the door’s finish. Inspect the door for signs of wear, rust, or damage, and address any issues promptly to prevent further deterioration.

Adjustments and Repairs

Regularly check the door’s alignment, hinges, and hardware to ensure smooth operation. Make any necessary adjustments or repairs to keep the door functioning properly. If significant damage or wear is observed, it may be necessary to replace the door or specific components.

Conclusion:

Hollow metal doors offer a multitude of benefits, making them an ideal choice for various applications, including commercial buildings, industrial facilities, and public institutions. Their durability, security, energy efficiency, and fire resistance contribute to their appeal. Proper installation and maintenance are vital factors in ensuring the performance and longevity of these doors.

FAQs

1. Can hollow metal doors be used for residential applications?

Yes, hollow metal doors can be used in residential settings; however, they are more commonly found in commercial, industrial, and institutional applications due to their specific benefits.

2. Can I paint my hollow metal door?

Yes, hollow metal doors can be painted using appropriate paints and primers designed for use on metal surfaces. Be sure to follow the manufacturer’s instructions for best results.

3. Are hollow metal doors more expensive than wooden doors?

While the initial cost of a hollow metal door may be higher than a wooden door, the long-term benefits, such as increased durability, security, and energy efficiency, can make them a more cost-effective option over time.

4. How long do hollow metal doors last?

With proper installation and maintenance, hollow metal doors can have a lifespan of 20 years or more, depending on the specific application and environmental factors.

5. Can I install a hollow metal door myself?

While it is possible to install a hollow metal door yourself, it is recommended to consult with a professional or follow the manufacturer’s guidelines to ensure proper installation and performance.