Perforated Filter: Precision Filtration for Industrial and Commercial Excellence

Introduction to Perforated Filters

A perforated filter is a specialized filtration component constructed from perforated metal sheets, designed with precise hole patterns to allow controlled passage of air, liquid, or solids. Known for their strength, durability, and high-performance efficiency, perforated filters are widely used across diverse industries such as oil and gas, food processing, pharmaceuticals, automotive, and water treatment.

These filters offer customizable flow characteristics, robust mechanical properties, and long-term resistance to extreme operational conditions. Whether it’s for coarse separation or fine filtration, perforated filters stand as a trusted solution in modern filtration technology.

Why Perforated Filters Are Essential

1. Superior Mechanical Strength

Unlike mesh or woven wire alternatives, perforated filters are fabricated from solid metal sheets, which means:

-

Enhanced pressure resistance

-

Higher load-bearing capability

-

Impact and wear resistance

-

Longer lifespan in harsh environments

This makes them the preferred choice in high-demand industrial processes.

2. Customizable Flow and Filtration Control

With a wide variety of hole shapes, sizes, and patterns, perforated filters can be tailored to meet precise performance requirements, including:

-

Fluid velocity control

-

Debris and particulate exclusion

-

Optimized throughput rates

-

Specific micron retention ranges

Filters can be designed for coarse screening or refined filtration, dependiendo de la aplicación.

3. Easy Cleaning and Maintenance

Thanks to their solid structure, perforated filters:

-

Resist clogging

-

Can be backflushed or pressure-cleaned

-

Are reusable and recyclable

-

Require less frequent replacements

This results in lower operating costs and minimal downtime.

Common Applications of Perforated Filters

1. Oil, Gas, and Petrochemical Industry

Perforated filters are extensively used in:

-

Pipeline strainers

-

Separator vessels

-

Gas scrubbers

-

Pre-filtration units

They help in removing particulates and contaminants to protect equipment and improve product purity.

2. Water and Wastewater Treatment

In environmental and municipal systems, they are used for:

-

Coarse filtration of solid waste

-

Sand and sediment exclusion

-

Drainage media filters

-

Pump and valve protection

Stainless steel perforated filters ensure corrosion resistance and hygienic performance.

3. Food and Beverage Processing

Hygienic-grade perforated filters are ideal for:

-

Juice and pulp separation

-

Milk processing and cheese making

-

Beer and wine filtration

-

Cooking oil recovery systems

These filters comply with strict sanitary standards and are easy to sterilize.

4. Pharmaceutical and Chemical Industries

Precision-engineered filters are used in:

-

Chemical reactors

-

Powder separation units

-

Air purification systems

-

Sterile processing equipment

Ellos ofrecen exact filtration tolerances and chemical compatibility.

5. Automotive and Heavy Equipment

Perforated metal filters are installed in:

-

Hydraulic systems

-

Fuel filtration units

-

Air intake and exhaust filters

-

Engine oil screening

They ensure machine longevity and system reliability under high-stress conditions.

Materials Used in Perforated Filters

1. Acero inoxidable (304, 316)

-

Corrosion-resistant and hygienic

-

Withstands high temperatures and pressures

-

Ideal para food, pharma, and marine environments

2. Carbon Steel

-

High strength and cost-effective

-

Adecuado para industrial and mechanical systems

3. Aluminio

-

Ligero y resistente a la corrosión.

-

Común en HVAC, automotive, and aerospace sectors

4. Latón y cobre

-

Excelente para decorative and antimicrobial applications

-

Often used in laboratories and boutique filtration systems

Types of Perforated Filters

1. Perforated Tube Filters

Cylindrical filters with uniform perforation around the surface, used in:

-

Oil strainers

-

Liquid flow systems

-

Dust collectors

They are easy to mount and provide 360° filtration.

2. Perforated Cone Filters

Designed for precision flow direction and minimal pressure drop, used in:

-

Spray systems

-

Mixing tanks

-

Jet engines and high-pressure valves

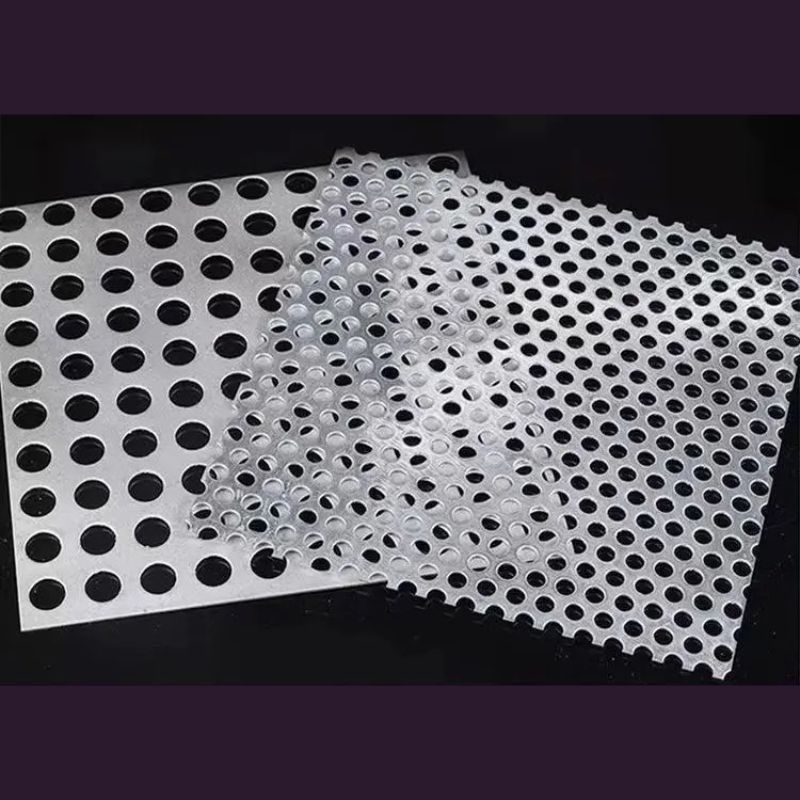

3. Flat Panel Perforated Filters

Used for:

-

Paneles de ventilación

-

Wall-mounted filter assemblies

-

Screening plates

These are often custom-cut and framed for easy integration.

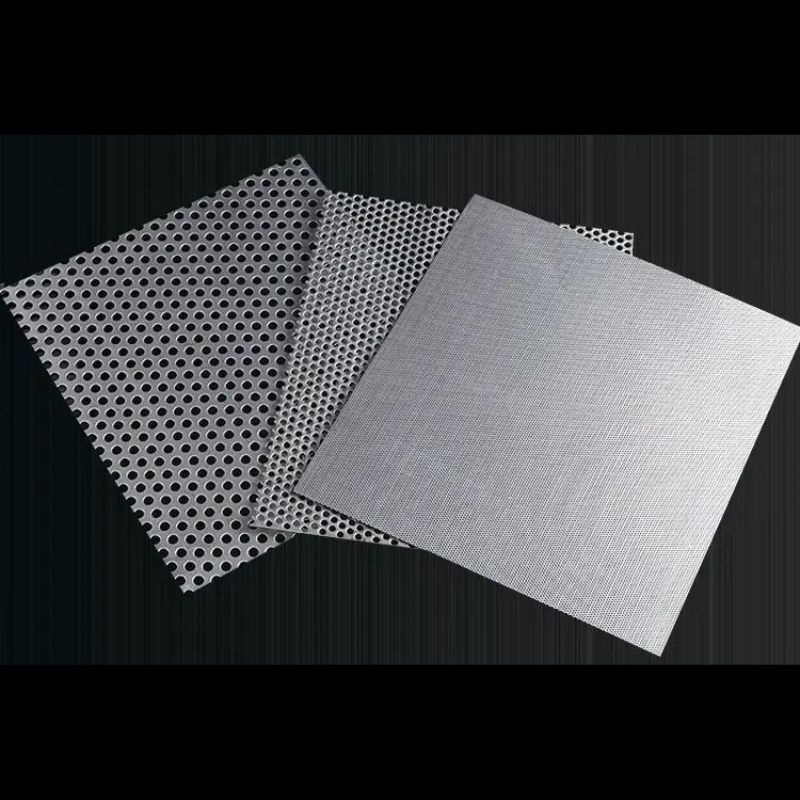

4. Layered Perforated Filters

Combine perforated sheet with wire mesh or filter media, ofreciendo:

-

Multi-stage filtration

-

Improved particulate retention

-

Enhanced flow dynamics

Perfecto para demanding chemical and pharmaceutical processes.

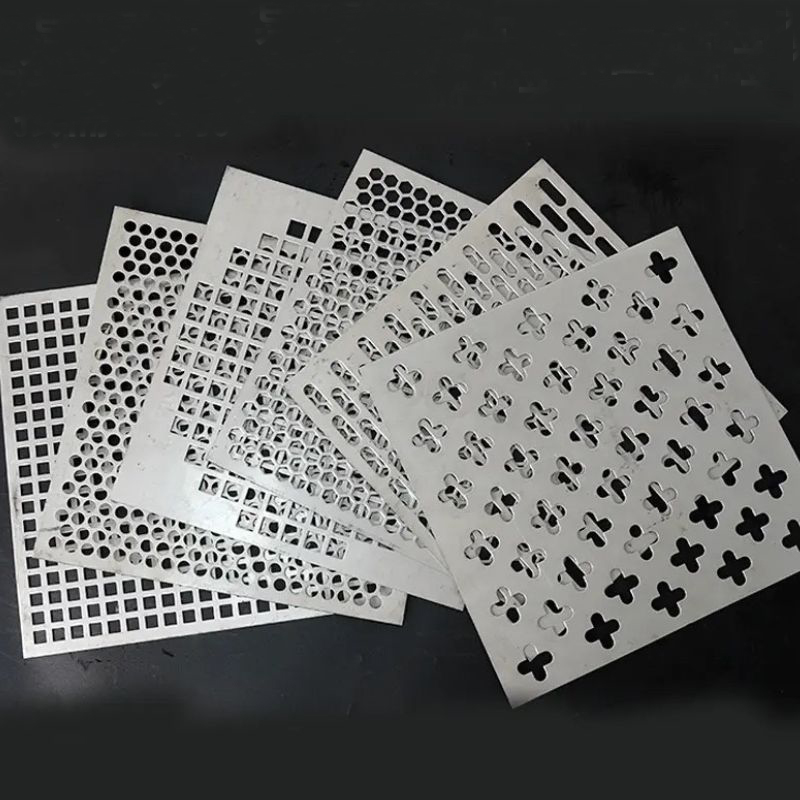

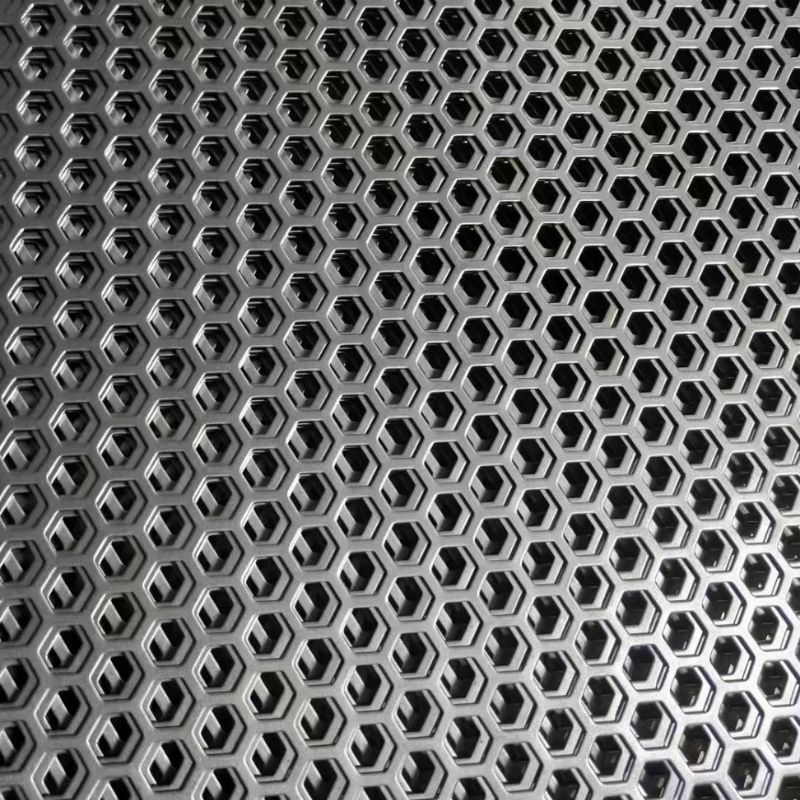

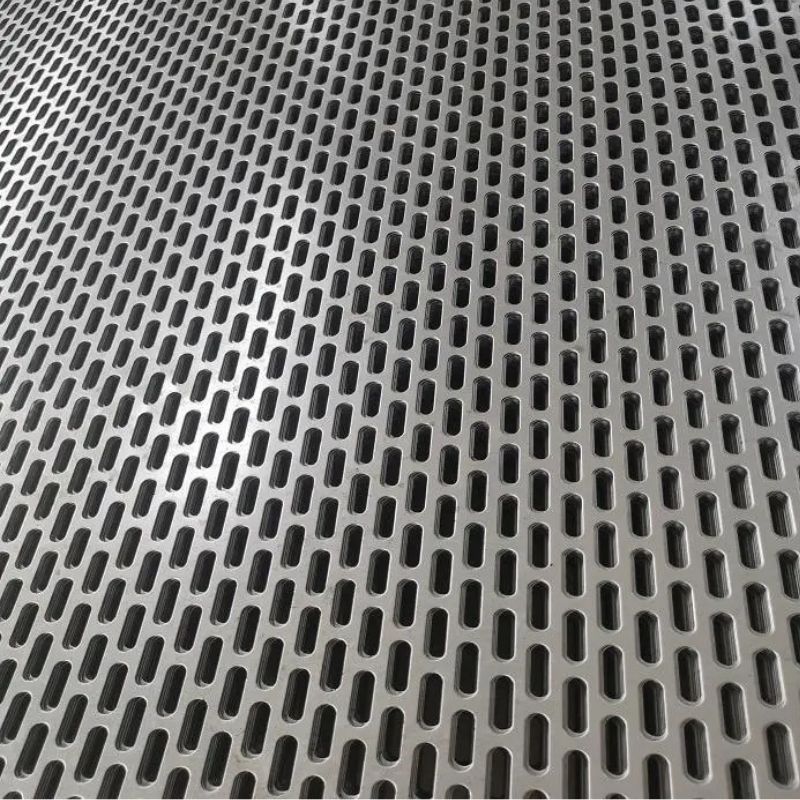

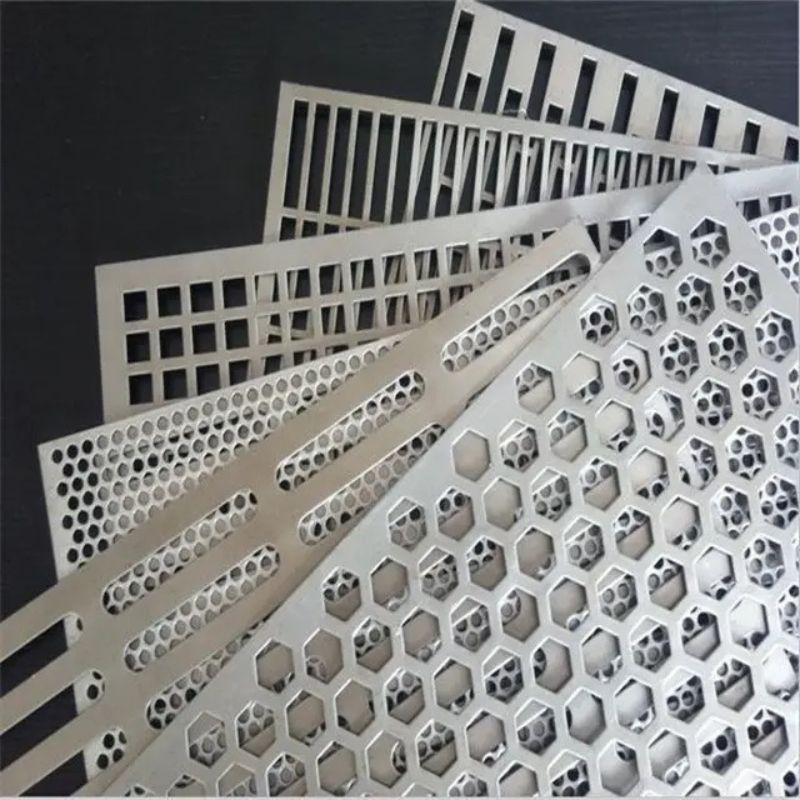

Hole Shapes and Patterns

Common Hole Types:

-

Round holes: Most common, ideal for uniform flow

-

Square holes: Higher open area, more aggressive screening

-

Slotted holes: Directional flow and increased throughput

-

Hexagonal holes: Maximum open area, honeycomb structure

Pattern Layouts:

-

Straight row: Clean and predictable flow

-

Staggered: Higher strength and filtration area

-

Custom patterning: Designed for brand aesthetics or performance tuning

Finishing and Treatment Options

-

Electropulido: Removes sharp edges and improves sanitation

-

Galvanizado: For rust resistance in steel filters

-

Anodizado: Especially for aluminum filters, improves corrosion resistance

-

Recubrimiento en polvo: Adds color and protective layer

-

Teflon Coating: For anti-stick applications

Selecting the Right Perforated Filter

When choosing a perforated filter, consider:

-

Medium type: Liquid, gas, or particulate?

-

Desired micron rating: How fine must the filtration be?

-

Flow rate requirements: Higher flow needs wider holes or more open area

-

Material compatibility: Will it be exposed to chemicals, moisture, or heat?

-

Mounting and integration: Does it require special housing or seals?

-

Certifications: Especially for food-grade or medical use

Conclusión

El perforated filter stands at the crossroads of engineering precision and filtration performance. Its ability to adapt to a vast array of applications, from industrial-scale oil refining to boutique beverage filtering, makes it one of the most dependable and versatile filtration solutions available today.

Whether you’re designing a high-volume liquid separation system o una cleanroom-grade air filter, a perforated metal filter delivers long-lasting performance, reliability, and design flexibility.

casssia@yoyimachinery.com

casssia@yoyimachinery.com