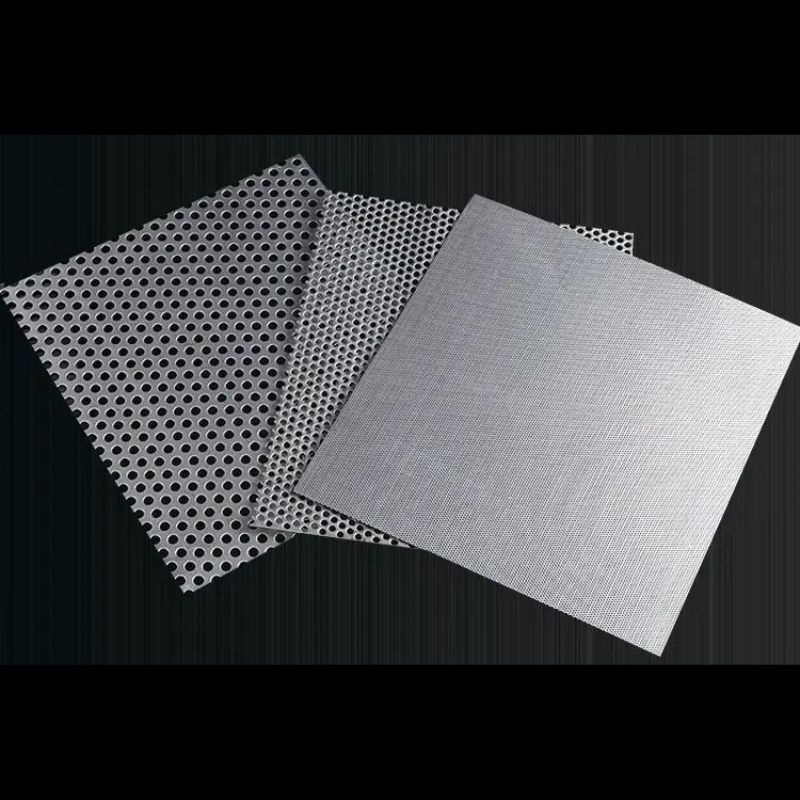

What is a Perforated Steel Sheet?

Perforated steel sheets are flat metal panels that feature a series of holes, slots, or decorative patterns uniformly punched into them using modern perforating equipment. These sheets are fabricated using carbon steel, galvanized steel, or stainless steel, making them highly versatile for numerous architectural, commercial, and industrial applications.

Common Applications of Perforated Steel Sheets

1. Architectural and Interior Design

In modern architecture, perforated steel sheets add both style and function. Their applications include:

-

Building facades and cladding

-

Sunshades and brise soleil systems

-

Interior panels and ceilings

-

Staircases and balcony railings

These sheets provide visual elegance, shade, and energy efficiency, making them a favorite among architects and designers.

2. Industrial and Manufacturing Use

Industrial sectors leverage perforated steel sheets for their reliability and adaptability in:

-

Machinery guards

-

Vibration dampeners

-

Filtration systems

-

Acoustic panels

-

Screening and separation tasks

The perforations can be tailored to control particle size, airflow, or noise reduction based on industry-specific requirements.

3. Automotive and Transportation

In automotive engineering, lightweight and corrosion-resistant perforated steel sheets are used in:

-

Grilles and exhaust systems

-

Sound-absorbing panels

-

Heat shields and ventilation components

These applications improve vehicle performance, aesthetics, and passenger comfort.

4. Agricultural and Food Processing

Perforated steel is extensively used in agriculture for:

-

Sorting trays and bins

-

Grain dryers

-

Food processing screens and conveyors

Its hygienic surface, ease of cleaning, and durability make it ideal for food-safe environments.

5. Security and Fencing

Security systems use perforated steel for:

-

Window and door security screens

-

Fencing panels

-

Protective barriers

El rigidity of steel with controlled visibility and airflow ensures effective security solutions.

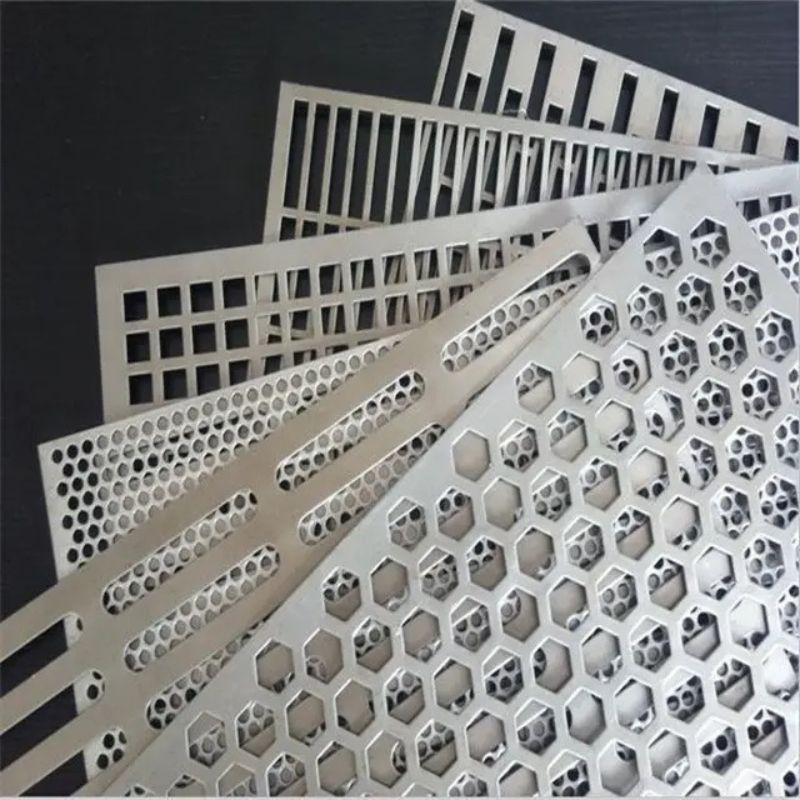

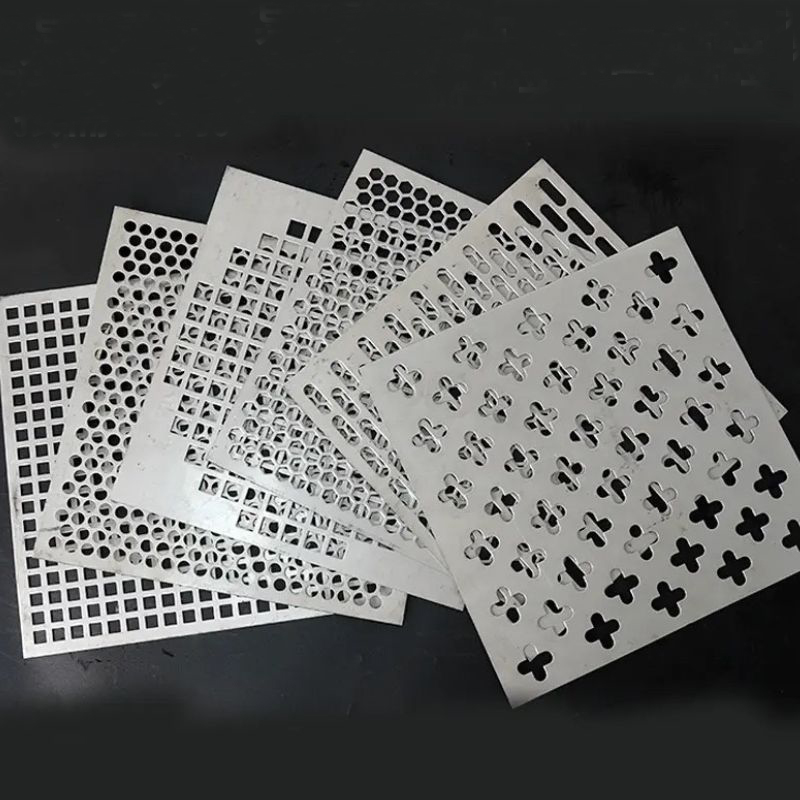

Types of Perforation Patterns

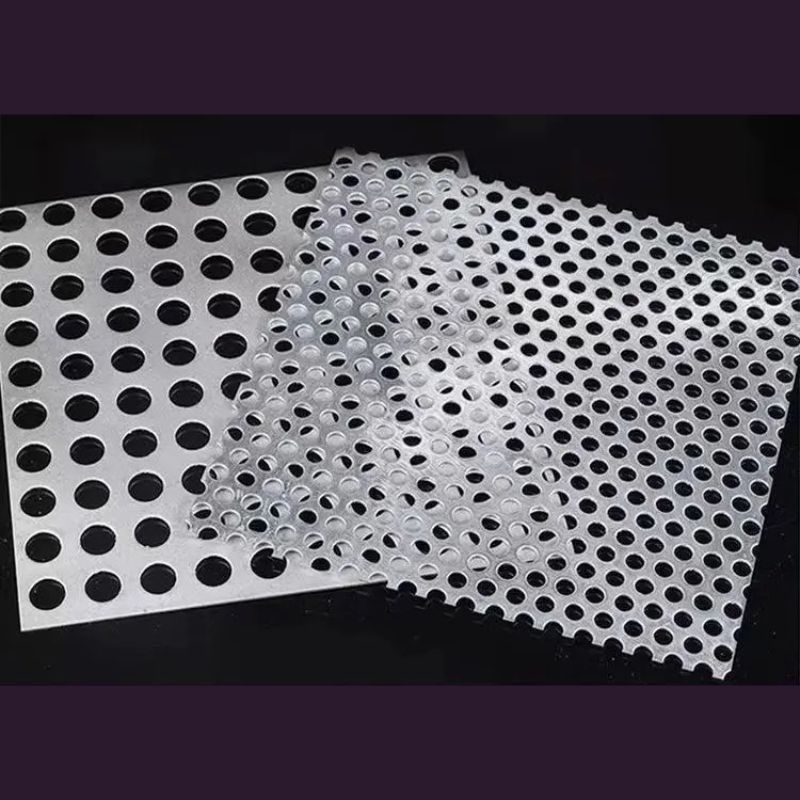

1. Round Holes

Round hole perforation is the most common type. It offers superior open area, making it ideal for:

-

Ventilation

-

Acoustic panels

-

Filtration screens

Available in staggered or straight-line patterns.

2. Square Holes

These provide a modern, bold appearance. Common in:

-

Decorative features

-

Retail displays

-

Machine guarding

Their symmetrical shape allows higher open area percentages compared to round holes.

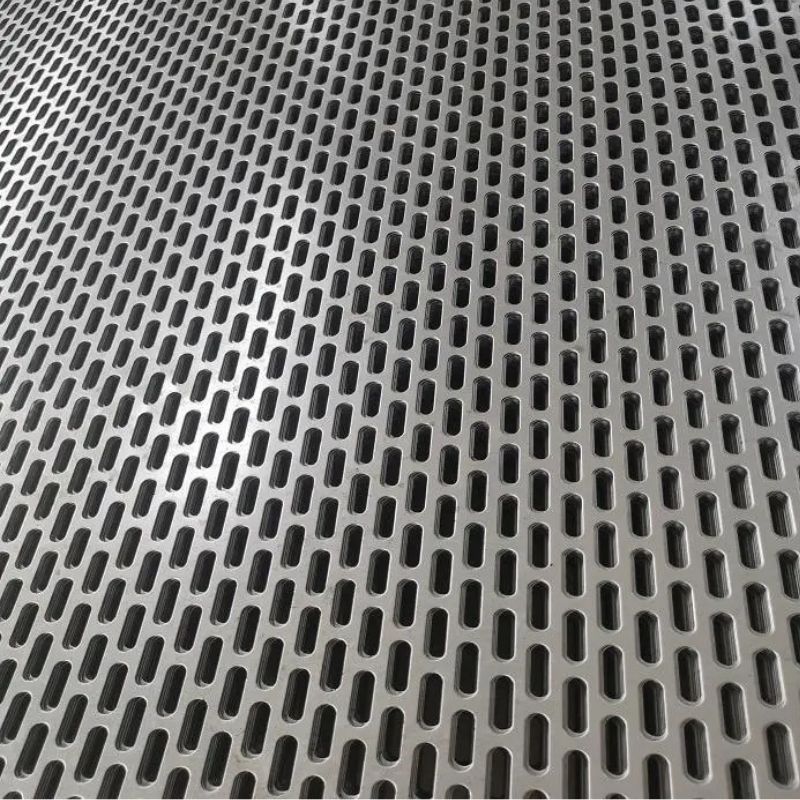

3. Slotted Holes

Used when elongated openings are needed, such as in:

-

Grain drying

-

Sieving

-

Water drainage systems

They are available in varied slot sizes and orientations to suit the flow of materials.

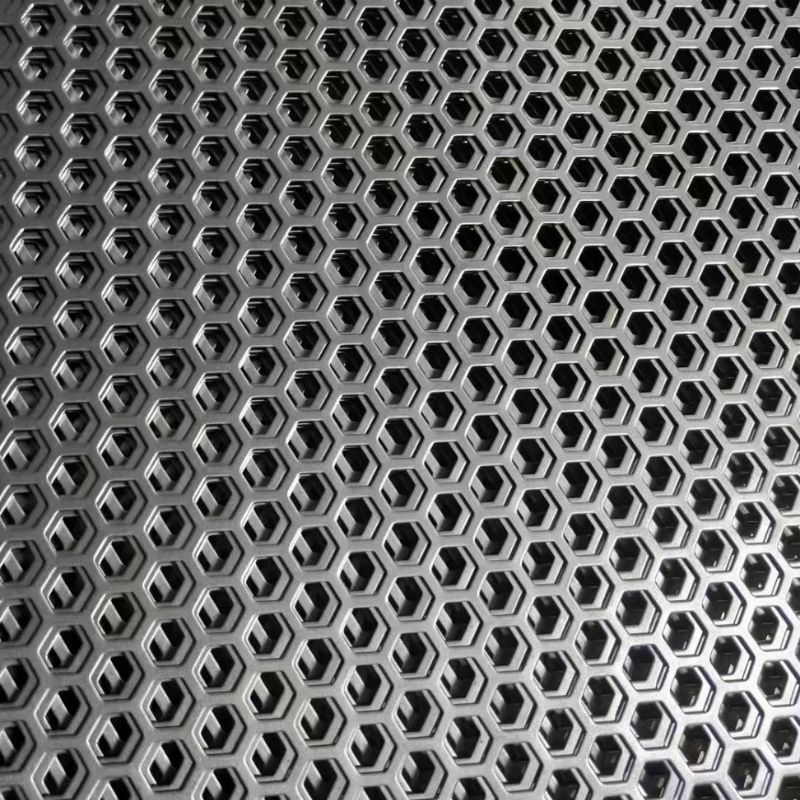

4. Custom Patterns

Advanced CNC punching systems enable customized shapes like:

-

Hexagons

-

Triangles

-

Ornamental designs

Used heavily in bespoke architectural projects and brand-specific signage.

Materials and Finishes

1. Carbon Steel Perforated Sheets

Ideal for heavy-duty industrial use, offering:

-

High tensile strength

-

Cost-efficiency

-

Wide availability

Can be painted or powder-coated for enhanced corrosion resistance.

2. Galvanized Perforated Steel

Coated with zinc to provide exceptional corrosion resistance, suitable for:

-

Outdoor installations

-

Marine applications

-

Rural infrastructure

Galvanization extends the material’s life significantly.

3. Stainless Steel Perforated Sheets

Best choice for hygienic and chemical-resistant applications such as:

-

Food and beverage

-

Medical facilities

-

Chemical processing

Grades such as 304, 316, and 430 offer varying resistance to heat, chemicals, and wear.

Manufacturing Process

Perforated steel sheets are produced using:

-

Rotary pinned perforation rollers

-

Punch presses with CNC precision

-

Laser cutting machines

Each method ensures high accuracy, repeatability, and customization. The process includes:

-

Sheet selection

-

Punching or cutting according to pattern

-

Deburring and surface treatment

-

Quality inspection and packaging

Advantages Over Other Materials

-

Stronger than aluminum and plastic alternatives

-

More versatile in pattern customization

-

Better resistance to deformation under stress

-

Longer lifespan under harsh environments

These advantages make it a go-to solution in demanding applications.

Customization and Fabrication Services

Manufacturers offer:

-

Custom hole sizes and spacing

-

Pre-cut dimensions or sheet formats

-

Bending, forming, and welding

-

Surface coatings (powder, paint, anodizing)

These services ensure the material fits perfectly into any project, reducing labor costs and installation time.

Buying Guide for Perforated Steel Sheets

When purchasing, consider:

-

Sheet thickness: Determines load capacity and weight

-

Hole size and pattern: Influences functionality and aesthetics

-

Open area ratio: Affects airflow, visibility, and weight

-

Finish and coating: Based on environmental exposure

Bulk orders typically offer cost savings, and many suppliers support custom orders with short lead times.

Conclusión

Perforated steel sheets combine strength, versatility, and aesthetics to serve a wide range of industries. Their capacity to allow airflow, light passage, and visual appeal without compromising structural integrity makes them an indispensable material in construction, manufacturing, agriculture, and design.

casssia@yoyimachinery.com

casssia@yoyimachinery.com