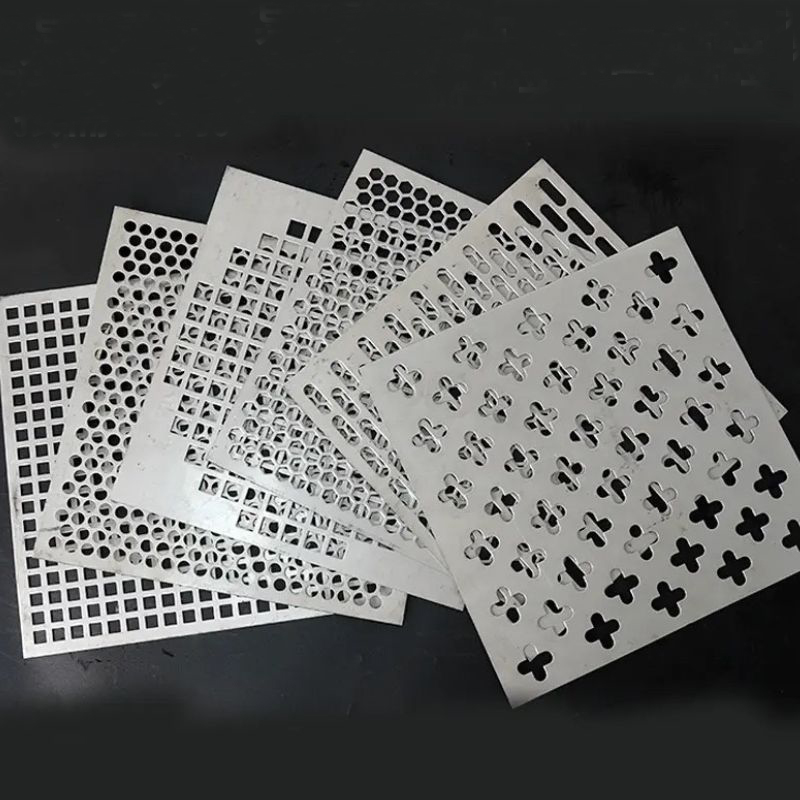

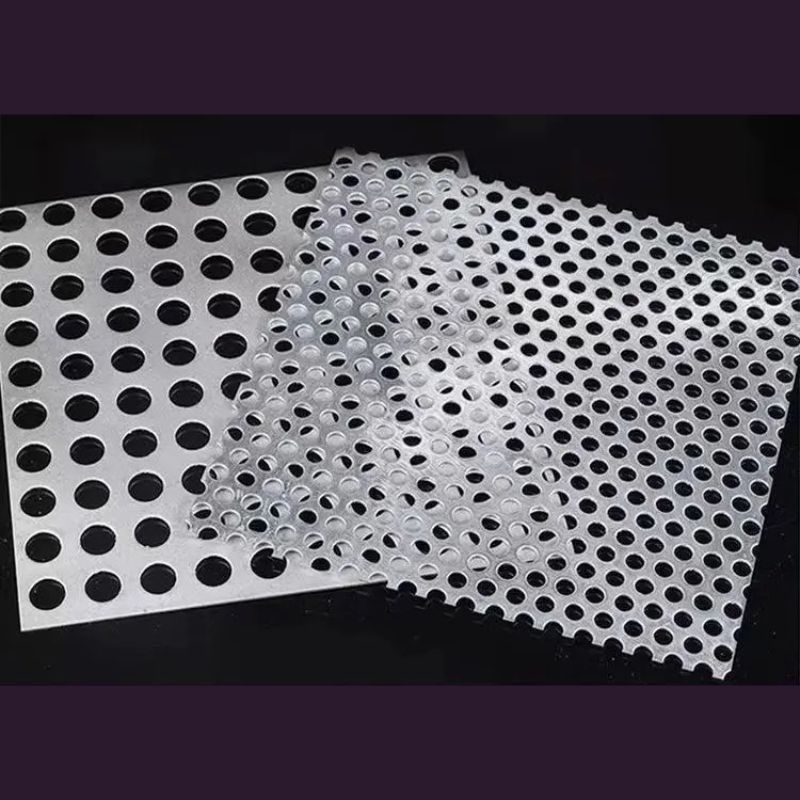

مقدمة عن الصفائح المعدنية المثقبة السداسية

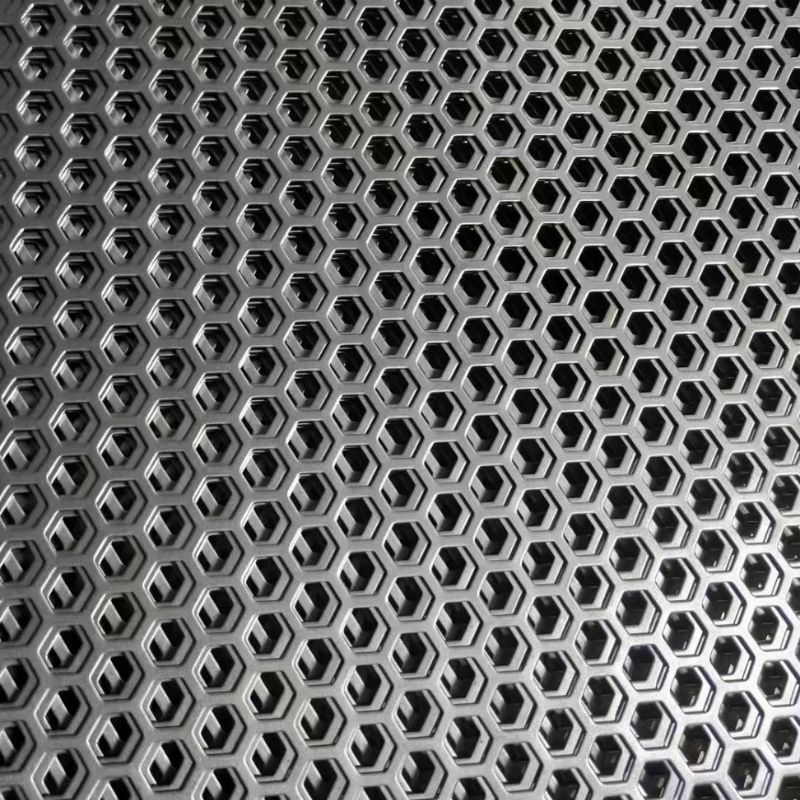

أ صفائح معدنية مثقبة سداسية الشكل هو منتج معدني هندسي يتميز بـ ثقوب سداسية الشكل مثقبة بالتساوي على سطح صفيحة معدنية صلبة. هذا التصميم الفريد لا يوفر فقط مظهر حديث يشبه قرص العسل ولكنه يقدم أيضًا لا مثيل له القوة وكفاءة تدفق الهواء والتنوع عبر التطبيقات المعمارية والصناعية والميكانيكية.

مع الحد الأقصى للمساحة المفتوحة لكل وحدة، سلامة هيكلية متفوقة، وجماليات مميزة، صفائح مثقبة سداسية الشكل أصبحت بسرعة الخيار الأول في قطاعات التصميم والهندسة المتطورة.

لماذا تختار صفائح المعدن المثقبة السداسية؟

1. كفاءة عالية في المناطق المفتوحة

توفر الثقوب السداسية واحدة من أعلى نسب المساحة المفتوحة بين جميع أنواع الثقب. وهذا يؤدي إلى:

-

تحسين التهوية ودوران الهواء

-

الترشيح عالي الأداء

-

هيكل خفيف الوزن ولكنه قوي

-

تحسين الصرف والرؤية

ال تكوين قرص العسل المحكم يسمح بإزالة المزيد من المعدن دون المساس بسلامة الورقة.

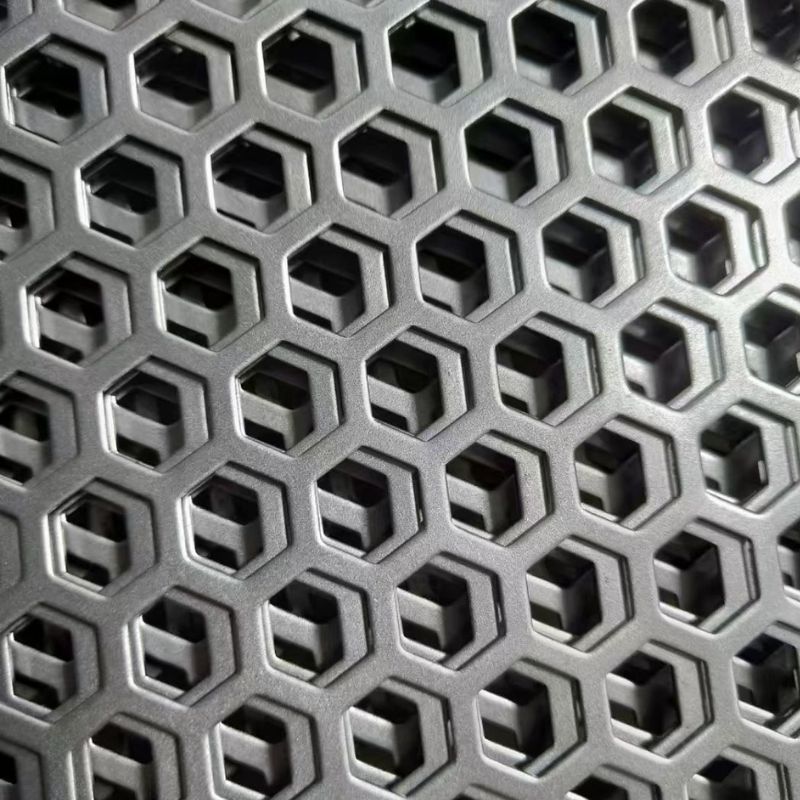

2. نسبة قوة إلى وزن استثنائية

صفائح مثقبة سداسية الشكل أقوى بطبيعتها بفضل تصميمها الهندسي، تُوزّع الضغوط على محاور متعددة. هذا يجعلها مثاليةً لـ:

-

التركيبات الحاملة للأحمال

-

الألواح الواقية والحراس

-

الكسوة المعمارية تحت الضغط البيئي

3. تصميم مميز بصريًا

ال يوفر النمط السداسي الأناقة الحديثة والتناغم الهندسي، مما يجعلها مفضلة لـ:

-

واجهات زخرفية

-

بلاط السقف والجدران المميزة

-

الأثاث والبنية التحتية العامة

-

عروض البيع بالتجزئة وعناصر العلامة التجارية

4. إدارة الضوضاء والضوء

النمط السداسي يعمل كـ مرشح صوتي ومرئي، مناسبة ل:

-

ألواح عزل الصوت

-

موزعات ضوء الشمس

-

شاشات الخصوصية

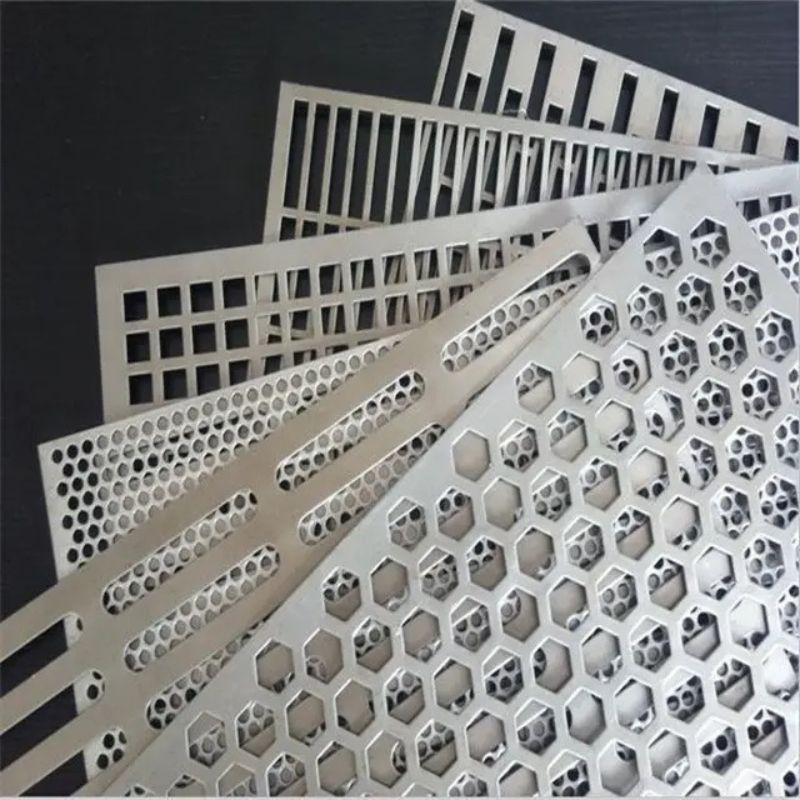

التطبيقات الرئيسية للصفائح المثقبة السداسية

1. المنشآت المعمارية والزخرفية

يستخدم المهندسون المعماريون والمصممون هذه الأوراق من أجل:

-

كسوة المباني والجدران الستارية

-

الأسقف المعلقة

-

الأقسام الداخلية

-

المظلات والبرجولات

تساعد قيمتها الجمالية العالية ووظيفتها تعزيز أداء البناء وجماله.

2. الاستخدامات الصناعية والهندسية

في البيئات التقنية، فإنها تعمل كـ:

-

حراس الآلات ودروع السلامة

-

مرشحات الهواء والسوائل

-

شبكات التهوية

-

أجزاء نظام النقل والفرز

تعمل الثقوب السداسية على تقليل الانسداد وتوفر تدفق المواد بكفاءة.

3. الزراعة وتجهيز الأغذية

إن المساحة المفتوحة والعقارات سهلة التنظيف تجعلها مثالية لـ:

-

مناخل وفرز الحبوب

-

رفوف التجفيف

-

شاشات الصرف

-

وحدات تخزين جيدة التهوية

توفر أنواع الفولاذ المقاوم للصدأ النظافة ومقاومة التآكل.

4. النقل والبنية التحتية

تُستخدم في مشاريع السكك الحديدية والسيارات والمدن:

-

أغطية التهوية والقنوات

-

واقيات البطارية والمحرك

-

دعم لافتات الطرق السريعة

-

سياج الحاجز والدرابزين

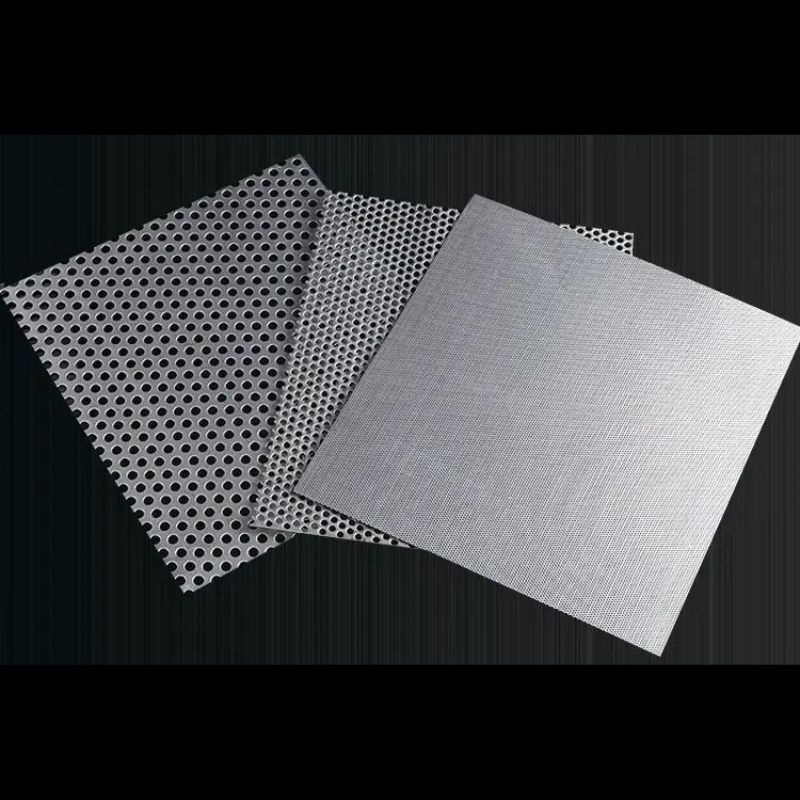

خيارات المواد للصفائح المثقبة السداسية

1. الفولاذ المقاوم للصدأ

-

مقاومة للصدأ والتآكل

-

درجات مثل 304 و 316 توفر المتانة في البيئات العدوانية

-

مثالي ل التطبيقات الغذائية والبحرية والطبية

2. الألومنيوم

-

خفيف الوزن ومقاوم للتآكل

-

مثالي ل الواجهات والنقل والألواح الصوتية

3. الفولاذ المعتدل

-

قوة عالية واقتصاد

-

يمكن طلائها أو طلائها بسهولة لمزيد من المتانة

-

تستخدم على نطاق واسع في آلات البناء والصناعية

4. الفولاذ المجلفن

-

مطلي بالزنك للحماية من الطقس

-

مثالي ل البنية التحتية الخارجية والاستخدام الزراعي

5. النحاس والنحاس الأصفر

-

مظهر غني مع خصائص مضادة للميكروبات

-

مفضل في الديكور الداخلي والتصاميم الفنية

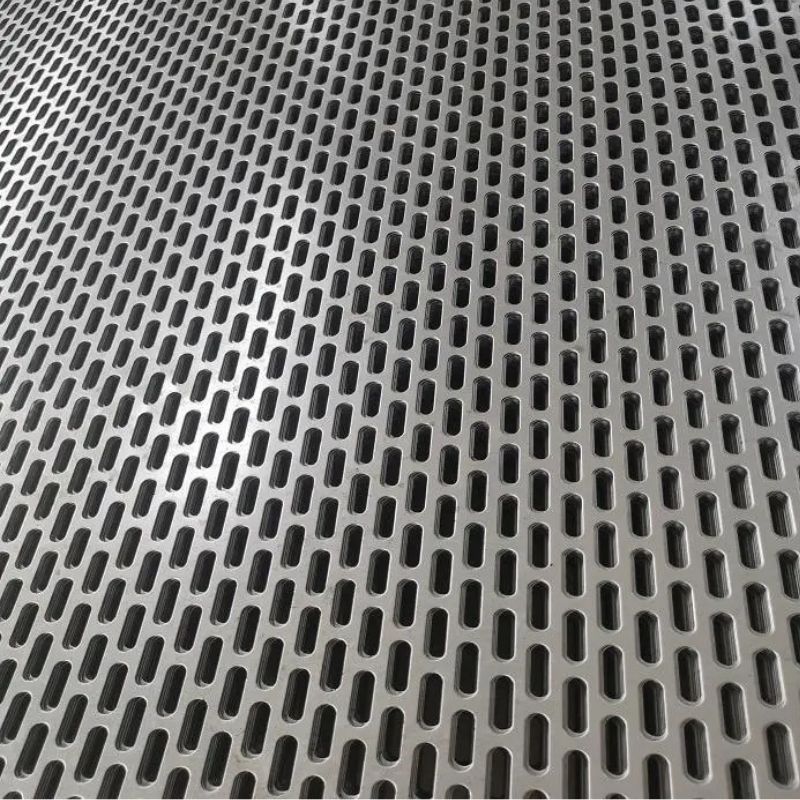

المواصفات وخيارات التخصيص

أبعاد الفتحة السداسية

أحجام السداسي الشائعة:

-

طول الضلع: 2 مم إلى 25 مم

-

يقذف:المسافة من مركز إلى مركز الثقوب المتجاورة

-

منطقة مفتوحة:غالبًا ما يتجاوز 75% في التكوينات المثالية

سمك الورقة

تتراوح من من 0.5 مم إلى 6 ممحسب احتياجات التطبيق. توفر المقاييس الأثقل دعمًا أفضل للحمل.

خيارات التخطيط

-

تخطيطات مستقيمة أو متدرجة

-

مدعومة بشبكة أو وسائط ترشيح

-

الأشكال والأشكال المقطوعة حسب الطلب

توفر العديد من الشركات المصنعة أوراق مخصصة بالكامل لتلبية متطلبات التصميم والأداء الدقيقة.

التشطيبات السطحية

تعزيز الأداء والجماليات مع:

-

طلاء مسحوق:يضيف اللون ومقاومة التآكل

-

الأكسدة (للألومنيوم): يزيد من الصلابة وخيارات الألوان

-

الجلفنة:الوقاية من الصدأ على المدى الطويل

-

التلميع أو التنظيف بالفرشاة:للحصول على لمسة نهائية معمارية أنيقة

-

تشطيبات الطلاء: للعلامات التجارية أو المطابقة البيئية

اختيار الصفيحة السداسية المثقبة المناسبة

قبل الشراء، قم بتقييم:

-

تطبيق الاستخدام النهائي

-

متانة المواد المطلوبة

-

حجم الحفرة المطلوب والمساحة المفتوحة

-

التفضيلات الجمالية

-

سمك التعامل مع الأحمال

-

التعرض البيئي

يمكن توفير حلول مخصصة مقطوعة باستخدام الحاسب الآلي، مطوية، ملحومة، أو منتهية لتلبية أي طلب صناعي أو معماري.

خاتمة

أ صفائح معدنية مثقبة سداسية الشكل يجمع لا مثيل له تطور التصميم وكفاءة المنطقة المفتوحة والسلامة الهيكلية.تمتد تطبيقاتها عبر التصميم والهندسة والتصنيع والبناء، مما يوفر مزيجًا مقنعًا من الجمال والوظيفة.

سواء تم استخدامها ل التهوية، والترشيح، والديكور، أو الحماية، توفر صفائح مثقبة سداسية الشكل أداء من المستوى التالي وتميز بصري.

casssia@yoyimachinery.com

casssia@yoyimachinery.com