Perforated Steel Sheet: Comprehensive Overview

Definition:

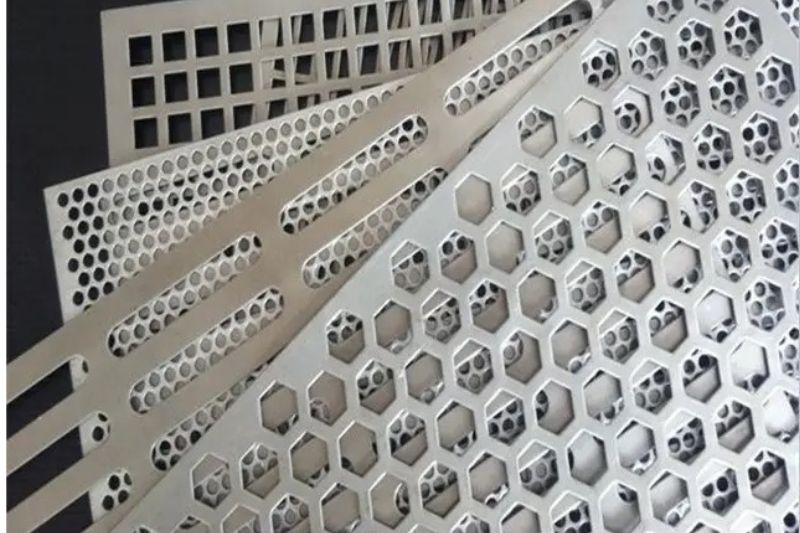

A perforated steel sheet is a flat steel panel with an array of holes systematically punched, drilled, or laser-cut into it. These holes vary in size, shape, and pattern, tailored to specific functional or aesthetic requirements.

Manufacturing Processes:

-

Punching: Utilizes dies for high-volume production, efficient for standard patterns.

-

Laser Cutting: Offers precision for intricate designs, ideal for custom applications.

Materials:

-

Carbon Steel: Common, cost-effective, but requires coatings for corrosion resistance.

-

Stainless Steel: Corrosion-resistant, ideal for harsh environments.

-

الصلب المجلفن: Zinc-coated for outdoor durability.

Hole Patterns:

-

Staggered/Straight: Enhances structural integrity or aligns for uniformity.

-

Square/Slotted: Functional for specific filtration or directional airflow.

-

Round/Hexagonal: Common for versatility; hexagonal mimics honeycomb strength.

التطبيقات:

-

Architecture: Decorative façades, sunscreens, balustrades.

-

Industrial: Machinery guards, filters, sieves.

-

Acoustics: Sound-damping panels in theaters or studios.

-

Safety: Anti-slip flooring, ventilation grilles.

-

Automotive: Exhaust systems, grilles.

Advantages:

-

Ventilation/Airflow: Facilitates cooling and air passage.

-

Strength-to-Weight: Maintains structural integrity despite perforations.

-

Aesthetic Flexibility: Custom patterns enhance visual appeal.

-

Customization: Adjustable hole size, spacing, and material thickness.

Key Considerations:

-

Open Area Percentage: Balances airflow with structural needs.

-

Thickness: Affects durability and hole-forming capabilities.

-

Corrosion Resistance: Material choice critical for outdoor use.

-

Hole Size/Shape: Dictates functionality (e.g., filtration vs. drainage).

Environmental & Maintenance:

-

Recyclability of steel supports sustainability.

-

Coatings (e.g., powder coating) enhance longevity.

-

Regular cleaning prevents clogging in filtration roles.

Design & Installation:

-

Patterns create dynamic light/shadow effects in architecture.

-

On-site modifications require careful cutting to avoid distortion.

Examples:

-

Subway platform screens, industrial sieves, acoustic panels, building façades.

Potential Issues:

-

Clogging in dirty environments; mitigated by periodic maintenance.

-

Sharp edges may require deburring for safety.

خاتمة:

Perforated steel sheets merge functionality with design, offering solutions across industries. Material selection, pattern design, and manufacturing techniques are pivotal in optimizing performance for each application.